|

2.1 SBT SYSTEMS

Before 1978, one of the tanker procedures which has most frequently

resulted in operational pollution of harbours was taking ballast following

the discharge of cargo. In 1978, the International Maritime Organization

adopted the MARPOL 1978 Protocol. This comprehensive anti-pollution

agreement includes requirements for certain ships to be provided with

ballast tanks, pumps and pipelines which are completely 'segregated'

from the ship's cargo systems. Ships whose ballast systems meet the

applicable requirements are certified as Segregated Ballast Tank (SBT),

tankers.

The SBT tanks are required to be protectively located on all 'new' crude

carriers over 20,000 DWT and all 'new' product carriers over 30,000

DWT. The protective location is intended to reduce accidental pollution

due to collision or stranding. The SBT tanks can contain sufficient

ballast to achieve an amidship draft in meters of 2 + 0.02 x LBP, with

the propeller immersed. This is enough for all but hurricane or typhoon

conditions if course and speed are properly adjusted in heavy weather.

Additional ballast can be taken in the ship's cargo tanks if the master

thinks it necessary. This is done by means of a special pumproom cross-over

connection (removable spool piece or blind), between the ballast and

cargo systems. Heavy weather ballast carried in cargo tanks which have

been crude oil washed but not water washed must be handled as dirty

ballast.

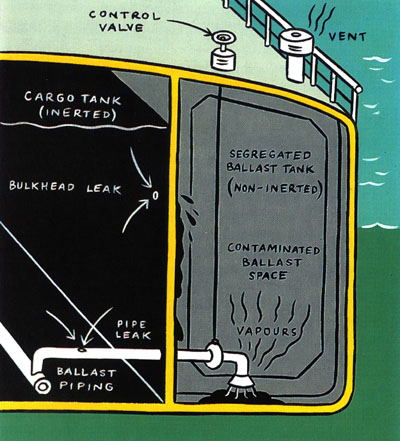

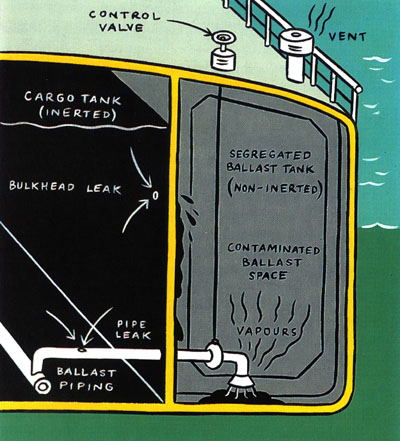

2.1.1 SBT pollution

SBT is not a fail-safe means of preventing pollution. Petroleum cargo

can enter the SBT tanks through bulkhead leaks. SBT tanks can also be

contaminated by cargo leaking into ballast piping which passes through

cargo tanks, or by cargo leaking out of cargo piping which passes through

ballast tanks. To maintain the maximum pollution safeguards while using

SBT, routine operational checks and piping integrity tests must be carefully

followed.

Bulkhead leaks or ballast piping leaks can be

sources of SBT contamination producing pollution and explosion hazards.

Case study

In June 1987 and March 1989, two different vessels commenced taking on

ballast water into segregated tanks by gravity (without use of the ballast

pumps), soon after commencement of discharge of cargoes of crude oil.

Unknown to the vessel's crews, the ballast lines had fractured within

the cargo tanks through which they passed. Instead of ballast water flowing

into the ship, the greater head pressure of oil in the cargo tanks caused

about 25 barrels and 35 barrels, respectively, of oil to escape via the

segregated ballast sea valves into the harbour.

Case analysis

If the vessel had maintained a program of ballast line integrity checks

on each ballast voyage, the defects should have been discovered and the

pollution incident avoided. If there is any doubt about the integrity

of ballast lines on a ship, then ballast should only be loaded by pumping.

In this case, t he ballast tanks would have later been found contaminated

by cargo, but that would have been an easier problem to fix than a pollution

incident.

2.1.2 SBT operations in the discharge port

Before taking on ballast at the discharge port, it is advisable to vapour

test the atmospheres of the ballast tanks. Before taking on SBT, open

the tank filling valve a few minutes prior to opening any other valves.

Then inspect the ballast tank for any oil ingress as stated. Presence

of hydrocarbon vapours in a ballast tank will indicate either a bulkhead

or pipeline leak. Whatever the cause, the ballast piping to the affected

tank will have to be flushed, and the tank washed before it can be used

for clean ballast. The tank may be ballasted without washing, but the

ballast will have to be handled as 'dirty ballast' when it is discharged.

The required entry must be made in the oil record book.

2.1.3 SBT contamination procedures

Once any contaminated ballast tanks have been suitably cleaned and ballasted,

the vessel may depart for sea.

After the vessel is at sea, the cargo tank(s) adjacent to the contaminated

ballast tank can be washed, ventilated and entered to examine the adjacent

ballast tank bulkhead for leaks. (Keep in mind that some cracks will

leak with pressure on one side, but will be forced closed by pressure

on the other side - 'one-way leaks'!) If the leak is located, the ballast

tank can be emptied and the leak cold-patched with composition adhesive.

The location of the leak must be reported to owners/managers for permanent

repair at the earliest opportunity. After the ballast is discharged

at the loading port, the ballast tank can be ventilated and entered

and the other side of the leak temporarily repaired, if necessary, before

cargo is loaded.

If no bulkhead leak can be found, and particularly if the contamination

appears in more than one ballast tank, a pipeline leak should be suspected.

Test for a pipeline leak by leaving the ballast suction/fill valve to

an affected ballast tank open during the ballast voyage and look for

an accumulation of water in the empty cargo tanks. The water will indicate

the location of the leaking pipe section. When the leak is located the

cargo tank must be washed and ventilated and the affected section of

pipe clamped to restore ballast system integrity until a permanent repair

can be made. The installation of the pipe clamp, the type of clamp used,

exact location of the leak, and the names of personnel who made the

temporary repair must all be recorded in the preventive maintenance

program record. The leaking pipe section must be scheduled for a permanent

repair at the earliest opportunity, not later than the next shipyard

period.

2.1.4 SBT precautions

Normally SBT tanks are filled while the cargo is being discharged, and

emptied while cargo is being loaded. SBT provides an economic saving

by permitting the vessel to be able to sail immediately after completing

discharge of cargo. Without SBT, when the cargo has been discharged,

the ship would be in a 'hogged' condition, with the amidship empty and

the heavier bow and stern structures tending to arch the keel of the

ship. To prevent these stresses, ballast will normally be taken in the

amidship segregated ballast tanks first. The forepeak and afterpeak

ballast tanks are filled last.

SBT hatches must be kept closed when handling cargo or ballast to avoid

drawing hydrocarbon vapours into the tanks. (SBT tanks are not normally

connected to the IGS system.)

Do not overflow the ballast tanks in port: it may wash oily residues

from the deck overboard, causing pollution.

Vessels which ballast in rivers or shallow harbours tend to accumulate

sediment in their ballast tanks. Tanks with sediment accumulation should

be washed and if necessary entered and descaled on the loaded passage.

All confined space entry procedures must be followed while cleaning

ballast tanks.

2.1.5 SBT corrosion

Many SBT tanks are fitted with sacrificial anodes to protect the uncoated

steel structure. The chief officer must remember that the anodes only

protect those parts of the structure which are completely immersed in

ballast water. When ballast tanks are filled they should be pressed-up

to the deckhead after departure, and maintained 100% full throughout

the voyage. Any slack (ullage) in ballast tanks will promote accelerated

corrosion of the under-deck structure.

Reduce ballast tank corrosion by pressing up ballast

tanks to the deck while at sea.

2.1.6 Ballast tank icing

Vessel's entering Canadian, Norwegian, or other high-latitude waters

during the winter season should replace any fresh water ballast with

salt water to reduce the freezing point of the ballast. In extreme cold

weather, when even salt water ballast may freeze, tanks should be left

slack. Before discharging, fill the tanks sufficiently to break up any

ice against the under-deck structure. This will prevent the ice from

forming on or clinging to the under-deck area in large chunks which

may damage ullaging equipment or ladders when falling to the tank bottom.

2.1.7 Written ballast plan

The chief officer must prepare a ballasting plan for each loading and

discharge port. The plan may be part of the general loading or discharge

plan, in which case it should be set out in a separate section. The

plan is prepared by considering the berth draft and freeboard restrictions

and stresses on the hull resulting from the off-loading plan. The plan

should be issued to the watch officers before arrival at the port so

that it can be reviewed by them and discussed as necessary.

|