|

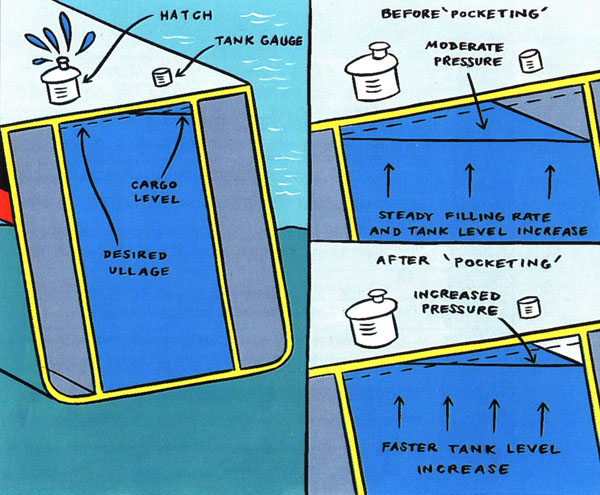

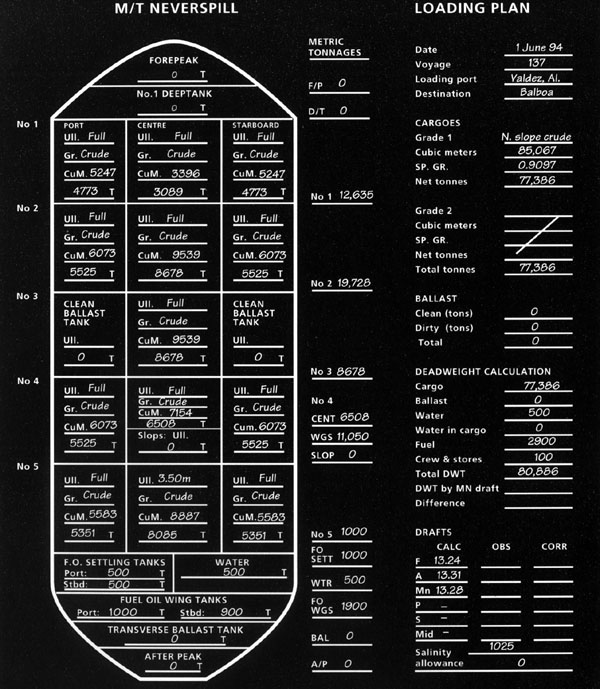

2.20 PREPARING THE LOADING PLAN

The loading plan for a tanker must address a multitude of requirements

including carrying capacity, hull stresses, loading and discharge instructions,

parcel separation, sequence of loading and discharge, vapour pressure,

expansion and contraction. A properly prepared cargo loading plan begins

with the most basic requirements and proceeds through a review of all

other essential considerations. The objective is to adequately ensure

the safety of the cargo at a minimum preparation expense in time, fuel

and effort.

In sections 2.8 and 2.9

the process for selecting a preliminary cargo layout was examined. By

the time the tank washing and tank cleaning operations have been completed,

the tanker should have received the final loading orders and any necessary

clarifications.

Loading orders may have been prepared in some detail by the owner's

or charterer's shore staff and may already represent the optimum loading

for the ship. Even detailed loading instructions must never be implemented

without careful review by the chief officer and master. The responsibility

for safe loading of the ship always rests with the master!

2.20.1 Loadline, loadline zones and loadline seasons

The International convention on loadlines, 1966, (with amendments

of 1971, 1975 and 1979), had the objective of establishing a uniform

set of requirements to prevent the overloading of ocean going vessels.

The desired outcome was the assurance that a ship would always leave

port with enough freeboard to provide the necessary margin of safety

against the weather and accidents which may be encountered during the

voyage.

The physical result of these agreements is the presence of the loadline

engraved on the side of each tanker. The practical implementation is

the chief officer's diligence in ensuring that the applicable loadline

is never submerged (on either side of the ship), when departing for

sea.

The chief officer must know exactly what draft is the limiting draft

when loading at and departing any given port. The complications are

the route of the ship, the season of the year and the salinity of the

water in the loading berth.

If the vessel is departing a port in a more restrictive zone (Winter)

and proceeding toward a less restrictive one (Summer) the ship cannot

be loaded below its Winter loadline mark. An example would be a tanker

loading at Valdez, Alaska and proceeding toward Panama. However, if

it is departing in a less restrictive zone and proceeding toward a more

restrictive one, it may depart with the limiting loadline immersed so

long as it consumes enough fuel to offset the immersion before entering

the more restrictive zone. An example would be a VLCC departing

the Arabian Gulf in November, bound for Rotterdam. The tropical loadline

applies at the time of departure, however the ship must have consumed

enough fuel and water by the time it passes the Mozambique Channel (20

degrees south latitude) that its summer loadline is not immersed and

enough additional fuel before passing Cape Torinana, Spain (44 degrees

north latitude) that its winter loadline is not immersed.

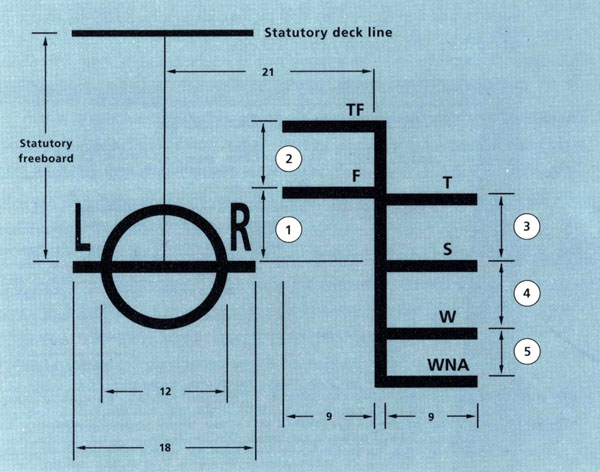

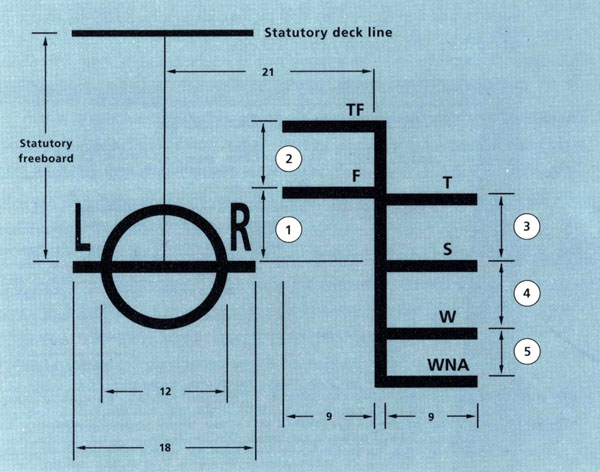

Load-line markings on the starboard side of an oil tanker.

1 Summer to fresh - ship's fresh

water allowance. 2 Fresh to Tropical fresh - one

forty-eighth of summer draft above fresh. 3 Summer

to tropical - one forty-eighth of summer draft. 4

Summer to winter - one forty-eighth of summer draft. 5

Winter to winter North Atlantic - for ships not more than 100 meters

(328ft) in length this distance is 50 millimetres (21 inches). For

other ships the winter north atlantic freeboard is the same as the

winter freeboard and is indicated only by 'W'. All measurements are

to be taken from the tops of the cross lines.

If the VLCC's tonnes per centimetre of immersion is 150 and the distance

between tropical and summer loadlines is 30 centimetres, then the tanker

would need to consume 4500 tonnes of fuel and water between the AG and

the Madagascar Channel in order to load to her full tropical marks on

departure. That is clearly impossible for even the thirstiest turbine

tanker! Nor would most ships be able to burn that amount of fuel between

the AG and Cape Torinana. The chief officer must therefore work backwards

from Cape Torinana, calculating the fuel burned to that point and loading

his ship to its Winter marks plus that amount. If the ship burns 60

tonnes per day and it is a twenty five day voyage to Cape Torinana,

then he can load to 10 centimetres over his Winter marks on departure:

60 tonnes/day x 25 days/150 tonnes/cm = 10 cm

This calculation must be done correctly, since the immersion of the

draft marks will be closely examined by port state control officers

on arrival and the fines for arriving with the ship overloaded will

be significant compared to the (approximately $3000), extra revenue

gained by loading another 10 cm.

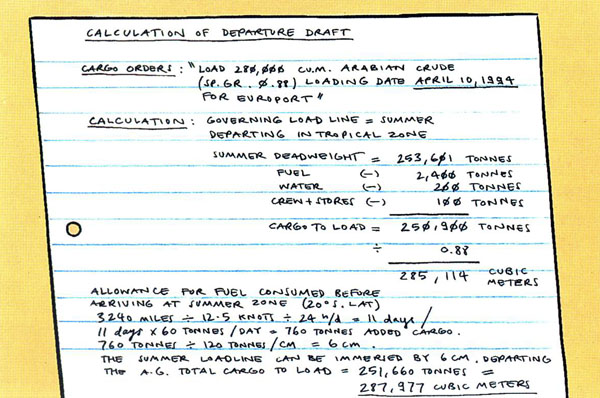

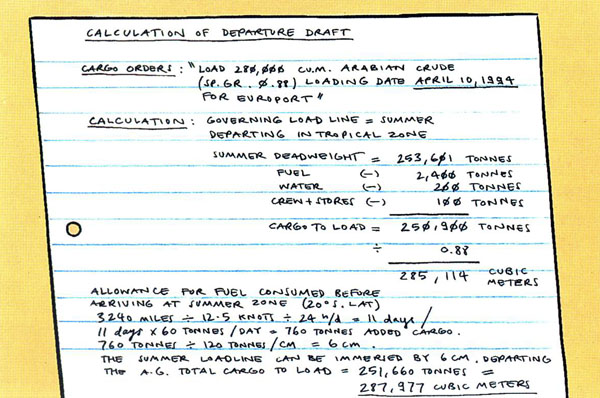

Calculation of departure draft and cargo quantity

where a loadline is the limiting factor.

The above calculation determinSes the deepest permitted draft from the

regulatory viewpoint. Other loading draft considerations include:

The available water depth at the loading berth.

Water density at the loading berth.

Depth of the departure channel and bar.

Depth over the bar at the delivery port.

Depth of water at the unloading berth.

Water density at the unloading berth.

With the departure draft known, the chief officer can use the Deadweight

Scale (or tables), to determine the equivalent deadweight tonnage allowed.

That calculation determines the total tonnage capacity of the ship.

The quantity of fuel water and stores and ROB cargo anticipated to be

on board at departure is subtracted from the total deadweight to obtain

the tonnage of cargo to be loaded. On loaded passage, the fuel, water

and stores should always be the minimum required to safely complete

the voyage. If the loading orders, do not provide adequate fuel and

water allowance, owners/ charterers must be advised of the discrepancy.

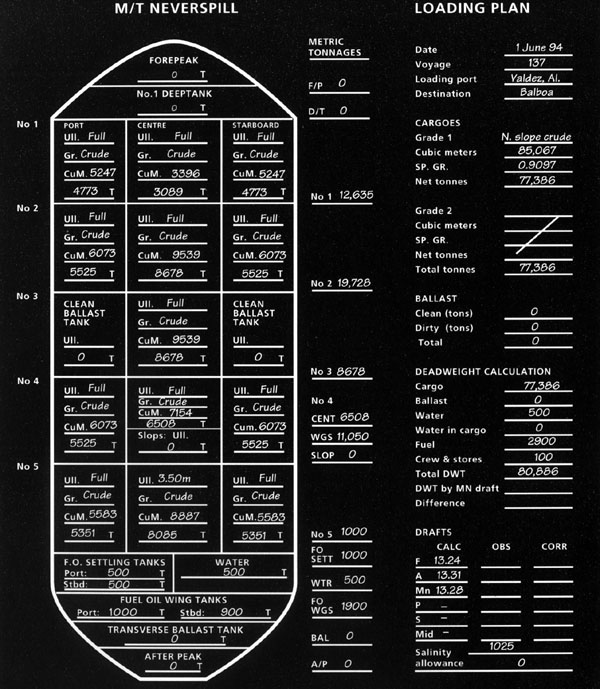

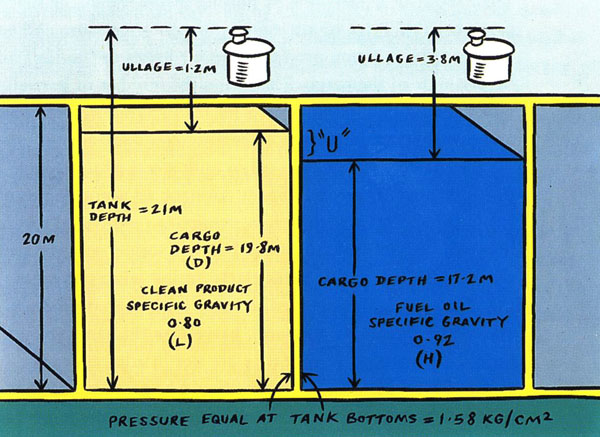

2.20.2 Cargo allocation - draft, stress and trim

Cargo allocation may be indicated in the owner's/charterer's voyage

cargo orders received, especially if parcels of different products or

crude oils are to be carried. If the orders are for a straight cargo

(all one grade), allocation by tank will probably not be indicated.

For a straight cargo, the chief officer will multiply the tonnes of

cargo to be loaded by the cubic meters per tonne factor of the cargo

to determine the cubic meters of capacity required. He must then allocate

the cargo among the ship's tanks to provide the desired trim within

permitted hull stress factors.

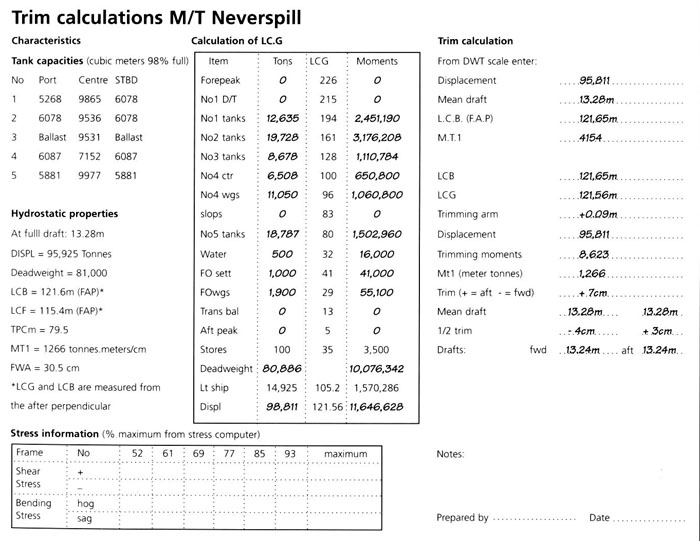

The task of allocating the cargo and calculating the resulting trim

and stress is best done by a loading computer. The loading computer

saves hundreds of hours of chief officer time and effort yearly and

eliminates the arithmetic errors found in manual calculations.

Nevertheless, an officer must understand the basis of the calculations

to use the loading computer efficiently and there is always the possibility

that the computer will fail, leaving only the manual method available.

The steps for completion of a manual calculation are:

1 Trial allocation of cargo volumes to each tank.

2 Calculation of cargo tonnages in each cargo tank.

3 Calculation of fuel, water and stores for the voyage.

4 Calculation of total displacement for the voyage.

5 Calculation of trimming moments for the proposed

loaded condition.

6 Calculation of the longitudinal centre of gravity

for the proposed loading.

7 Determine the longitudinal centre of buoyancy for the proposed loaded

displacement (from hydrostatic tables).

8 Calculation of total trimming moments.

9 Determine the moment to trim one centimetre (or inch),

from the hydrostatic tables.

10 Calculation of trim (forward or aft).

11 Calculation of cargo/ballast allocation change necessary

to achieve the desired trim, using two or more cargo/ballast tanks.

12 Calculation of bending and shear stresses resulting

from the desired loading.

13 Calculation of bending and shear stresses for the

arrival condition at the discharge port.

14 If the stress factors are acceptable, determine

the ullages for loading of trim tanks.

15 Independent verification of calculations by another

officer.

The examples indicates that the initial allocation of cargo results

in a trim of 7 cm forward (by the head). The trim can be adjusted to

zero (even keel), by reducing the cargo quantity in the No.l cargo tank

by 45 tonnes and adding 45 tonnes of ballast to the afterpeak tank,

or by shifting 78 tonnes from the No.l cargo tank to the No.5 cargo

tank. The first alternative reduces total bending stresses more than

the second alternative. If the bending stresses for the first cargo

allocation are near the maximum allowable for sea conditions, then the

first alternative is the preferred option.

For a mixed cargo loading, the chief officer should begin with the

recommended cargo allocation contained in the loading orders, completing

the deadweight, trim and stress calculations accordingly. If the plan

works and makes best use of the vessel's capacity, then owners/charterers

can be advised that it is acceptable and will be followed. If the plan

does not work, ie. it causes excessive stress or trim, does not permit

proper segregation of cargo parcels, or if it causes deadfreight which

could be reduced by an alternative arrangement, then the master should

advise owners of the discrepancy and advise a suggested alternative.

The alternative may be rejected or accepted (due to reasons other than

the best use of the ship) and the master will proceed with the cargo

plan as agreed, provided it is safe to do so.

When cargo calculations are being performed manually, the independent

verification by a second officer is essential. A junior officer should

be assigned to independently do the verification. The verification task

gets the junior officer more involved in the cargo operation and aids

the development of his skills.

On conventional tankers, transverse stability is not a serious concern.

With most or all of the cargo tanks full, the transverse stability (as

represented by the metacentric height or 'GM'), is more than adequate.

On some combination carriers (ore oilers, bulk oilers, or OBO's), with

wide centre tanks, the number of slack tanks must be limited at loaded

draft to ensure adequate transverse stability. For those ships, transverse

stability must be calculated along with the trim and stress in the loaded

condition. Transverse stability in bulk carriers must be calculated

at several steps during the loading to ensure that the free surface

effects of the tanks being loaded do not create and unstable (negative

GM), condition. The calculation of transverse stability is an assumed

skill of all ships officers and will not be discussed here.

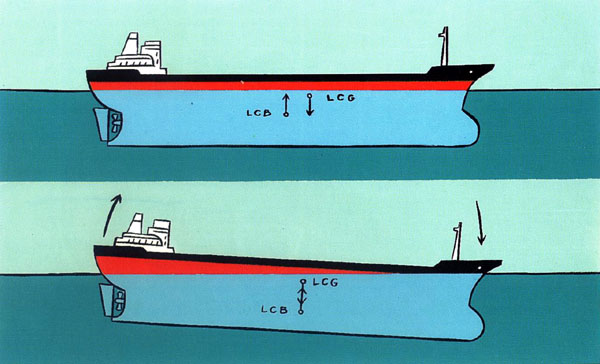

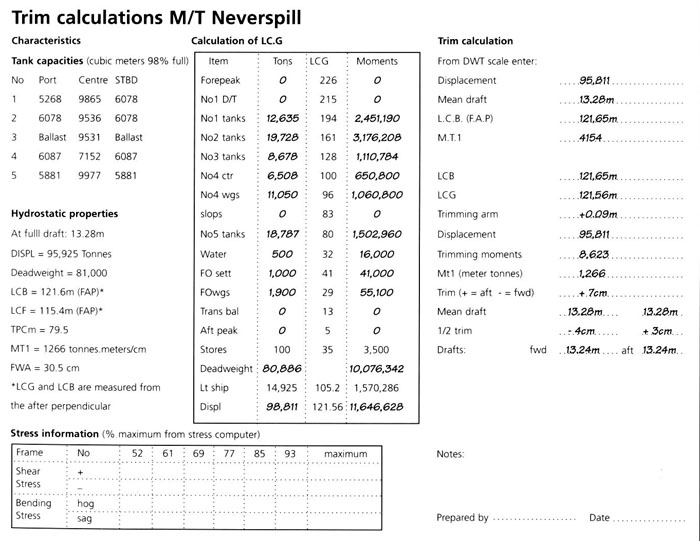

If LCB would be aft of LCG on an even keel, then

the ship will trim forward 'by the bow' until LCB moves under LGB.

The calculation of the cargo load should include a review of the arrival

condition of the ship at the discharge port. On some VLCC's it is necessary

to compensate for the consumption of bunkers to keep stresses within

safe limits. If loadline regulations allow, the required compensation

may be achieved by ballasting the after permanent ballast tanks or the

afterpeak. On other ships it may be necessary (with charterer's prior

authorisation), to transfer cargo so that the ship will arrive at an

even-keel trim. The stress conditions before and after the transfer

of cargo must be evaluated.

2.20.3 Separation, segregation and compatibility

The term 'compatible grades' means that two cargo parcels are similar

to the degree that they can be handled by the same pump and pipeline

system, after draining, without risk of contamination of either parcel.

Some cargo grades do not even require draining of pumps/pipelines between

parcels. When evaluating compatibility of cargoes, a number of critical

factors must be taken into account, including colour, flash point, pour

point, viscosity, specific gravity, sulphur content, lead content, gum,

water separation index, initial boiling point and vapour pressure (see

section 2.9.1). In addition, oil cargoes are classified

as 'clean' or 'dirty' according to their composition and handling characteristics.

Ships are normally restricted to carrying either clean or dirty cargoes

because of the risk of contaminating a clean cargo on a normally dirty

ship and the cost of trying to get a normally dirty ship clean enough

to carry a clean cargo. Between clean cargoes, flash point is the most

critical factor in terms of compatibility and special precautions must

be taken to prevent mixing between gasolines and other grades.

With dirty or black product cargoes, the question of flash point becomes

critical only when fuel oils are being carried with or after crudes.

Crude oil parcels must always be segregated from fuel oil parcels by

at least two valves, ie. 'double valve' protection.

Compatible grades can be loaded with single valve separation, provided

that the valve has been tested for tightness. This test is achieved

by applying liquid or air pressure on either side of the valve and observing

for leakage on the other side. The results of the test should be logged

and recorded in the maintenance journal/ program. Cargo operation should

be planned so that the separation valve(s) are not opened before the

contamination risk is passed at the discharge port.

Non-compatible cargoes must be completely segregated and cargo parcels

of different classes (ie. gasoline and heating oil), must be loaded

and discharged by separate cargo systems. Cargo parcels of the same

class, but of a different type (ie. two crude oils), may be handled

within a segregated cargo system.

On vessels with un-coated tanks, different grades must always be separated

by two closed valves (a master valve and a tank suction valve), due

to the possibility of the valve leaking from rust scale in the valve

seat. Ships which carry mixed parcels should pay special attention to

scale build-up underneath cargo valve discs. Scale accumulation may

prevent a valve from closing properly and result in a cargo contamination.

The problem of scale build-up is essentially eliminated in fully coated

tanks and single valve separation (with a master valve or a crossover

valve), may be permitted, provided there is program in place to regularly

verify valve tightness.

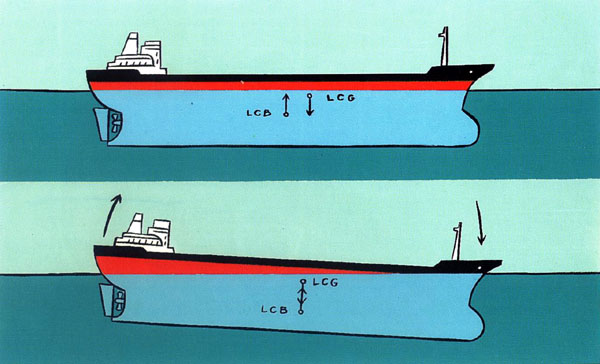

When planning the disposition of the various cargo parcels, care should

be taken to minimise the risk of contamination by undetected bulkhead

or pipeline leaks. If valve or bulkhead leakage is suspected, then the

adjacent grades must be loaded so that the more delicate product is

loaded to a smaller ullage (higher innage), than its neighbour. If the

more delicate product is a lower specific gravity (often the case),

then the difference in ullage must be large enough so that at the bottom

of the tank the delicate product still has a higher hydrostatic pressure

than the adjacent grade. If any leakage does occur, it will be from

the more delicate cargo into the less delicate cargo with less possibility

of that product being put 'off test'. The difference in ullage required

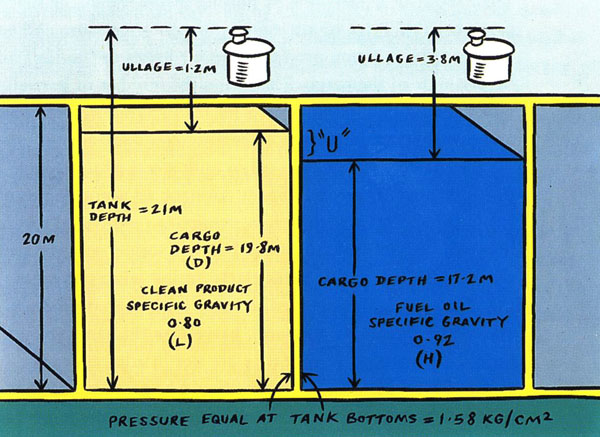

to provide for equal pressures at the tank bottom is:

U = D (H - L)/H

where:

U = ullage difference

D = depth of lighter parcel

H = heavier parcel sp. gr.

L = lighter product sp. gr.

This calculation yields the ullage difference required to produce

equal hydrostatic pressure at the bottom of adjoining tanks.

To provide a positive pressure from the lighter product tank into the

heavier product tank the ullage difference should be increased. Valves/hammerblinds

separating cargo parcels of different class should be sealed in the

loading port. These seals should not be removed until the cargo tanks

have been sampled at the discharge port and not until the first grade

of cargo has been discharged and the valve must be opened to complete

the cargo discharge.

To prevent leakage of fuel oil to the clean product

cargo depth of fuel oil must be less than 80/92 x the cargo depth

of the clean product.

Most tankers are configured to provide some segregation capability,

with the normal number of parcel divisions corresponding to the number

of cargo pumps and main cargo lines on board. A tanker with three pumps

should have the capability of segregating three parcels, while one with

four pumps may be able to segregate four. The volume of each of these

segregations is fixed by existing bulkhead, valve and pipeline configurations.

For carrying mixed parcels on one voyage, the objective of charterers

or owners is to arrange the volumes of the parcels so that they most

closely fit the natural segregation capabilities of the ship. When an

exact match cannot be achieved, it is better to arrange the parcels

so that a tank is left empty in one section, than to risk a contamination

by loading one or more tanks beyond the natural segregation barriers

of the ship.

Another source of contamination is common or collected vent systems.

When non-compatible cargoes are loaded into segregated tanks which share

a common vent system, the cargo ullages must be large enough to prevent

any cargo from sloshing into the vent system while rolling, and flowing

into another tank.

If tanks are only partly filled, the movement of the vessel will cause

the cargo to move, or slosh, in the tanks. In some circumstances, such

as harmonic rolling, the sloshing can be violent.

This results in a breathing or pulsing inside the ullage space and will

cause the P/V valve to alternately relieve on pressure and vacuum. This

breathing action produces vapour losses or 'boil off of the lighter

ends of the cargo. Therefore, the number of partially filled tanks should

be minimised as a means of avoiding breathing losses and possible tank

structure or heating coil damage.

Recent developments in cargo tank stress analysis have indicated that

some cargo tank bulkheads constructed according to older class rules

contain less strength than required to withstand severe stresses imposed

by harmonic sloshing. This is another reason to minimise the number

of slack tanks, particularly during winter voyages.

When a vessel is directed to carry both heated products and volatile

(high vapour pressure), parcels on the same voyage, the cargo should

be arranged so that they are not in adjacent tanks. If this cannot be

avoided, the stowage should be arranged so that the products have only

one adjacent bulkhead and the temperature of the heated product must

not exceed 65 �C.

Some product carriers have sufficient pumps and pipelines to dedicate

one to each parcel of cargo carried. When other tankers carry multi-grade

cargoes, it is necessary to load or discharge similar grades of the

same class via the same pipeline/pump system, accepting some down-grading

(of the more critical product into the less critical product), in the

loading and discharge operations. Where it is essential that no co-mingling

or downgrading occur, a pump pipeline and tank system will be dedicated

exclusively to the parcel, at least until it has all been pumped ashore

safely at the discharge port.

A useful precaution when handling parcels requiring two-valve separation

and strict sequencing of loading/discharging is to apply temporary labels

to all of the valve actuators. If the valves are operated by hand on

deck, they can be labelled with 5 cm masking tape stretched across the

handwheel and marked with an indelible marker. If the valves are operated

from the cargo control room, small, clear plastic boxes should be placed

over the critical valve controls (fastened with tape if necessary) and

a 'white board' marker used to label the box with an appropriate notice.

For valves which must absolutely remain closed, a small sketch of a

severed hand is usually an effective deterrent!

2.20.4 Loading and discharging sequence

For straight cargoes, the loading sequence needs to consider only the

stresses placed on the hull by the cargo and the sequence in which the

cargo is likely to be discharged. Cargo tanks are normally loaded in

'sets'. The first set is selected to minimise hogging stresses on the

ship while bringing the ship close to an even keel condition. The second

set loads the ship evenly and bodily down to near the maximum loaded

condition. The final set, called 'trim tanks' are used to complete the

loading of the cargo to the vessel's marks and even keel (or if adequate

water depth exists in the loading port, to a departure trim which will

provide an even-keel arrival trim at the discharge port). On a vessel

with wing and centre tank arrangement, the centre tanks should be loaded

first, since the extra framing in the wing tanks makes them better able

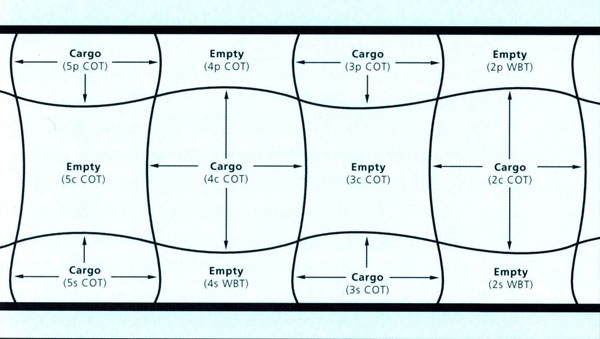

to support the outward pressure on the longitudinal bulkheads. 'Checkerboard'

loading sequences should be avoided because such arrangements stress

the bulkhead intersections unnecessarily.

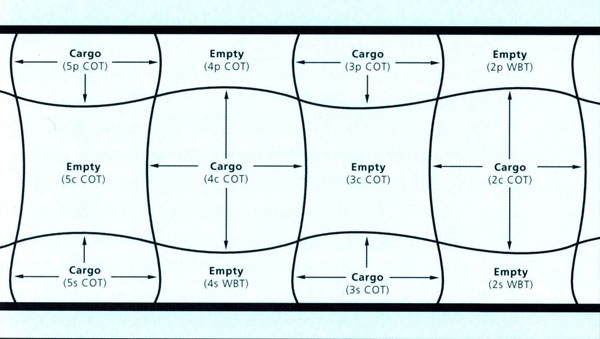

Alternating wing and centre ranks in the loading

pattern places tank bulkheads intersections under unnecessary stress

'Checkerboard' loading patterns should be avoided.

If the ship's designer has provided a recommended loading sequence

it should be followed whenever other cargo requirements permit.

Because of their slower state of decrease in ullage when topping off,

some chief officers prefer to use a centre tank rather than a wing tank

as the final tank to be filled. In that case, the centre tank to be

used for trim should be filled to 1/2 of its final ullage while loading

the other centre tanks, then stopped and reserved to receive the excess

flow while topping off the wing tanks. The loading can then be finished

in the desired centre or 'trim' tank. SBT ships require a closely integrated

loading and de-ballasting plan which minimises hull stresses during

loading.

Where multiple parcels are being carried in separate ship systems, the

primary considerations during loading are timing and hull stress. The

same stress criteria should be observed as with a straight cargo. However,

priority should be given to starting the grade of cargo which will take

the longest to load and to continuous loading of that grade (safety

permitting), until it is finished. Knowing which cargo will take the

longest requires information on shore loading rates which should be

requested by the master before vessel's arrival. This information may

be available on board from previous loadings at the same terminal. (See

section 2.20.5.)

Occasionally it will be necessary to carry two grades of cargo within

the same ship system. Such a procedure is never done without an element

of risk and the charterer should be advised of the master's objections

to doing so. Cargo parcels of different classes (i.e. heating fuel and

gasolines), should never be handled in the same system. Cargo parcels

of the same class but different type/grade (i.e. regular and premium

gasolines), may be handled in a single segregated system with proper

precautions.

Despite any objections recorded by the master, once orders have been

received to share a cargo system between grades, the vessel is still

responsible for making every effort to safeguard the cargo's quality.

For the loading operation, it is important to know which of the parcels

is the most delicate. With all the ship's pipelines clean and empty

before loading, the delicate cargo parcel should be loaded first and

blocked off as completely as possible in its tanks. The less delicate

parcel is loaded second. At the discharge port, the less delicate parcel

is discharged first. Then the pipelines are stripped dry and the more

delicate parcel is used to flush the lines into the shore line for the

first cargo. After the flush is completed, the shore lines are changed

and the delicate parcel can be safely discharged.

An alternative may be available if the two parcels are to share the

aft cargo system on the ship. With this arrangement, the less delicate

parcel is loaded first through the deck drop line and bottom lines,

into the forward tanks of the aft system. The bottom line block valves

between the two parcels are closed before loading begins. After the

first parcel has loaded the deck lines are carefully drained down to

the cargo tank, the deck drop valve is closed and the deck line block

valve is opened. The more delicate cargo is loaded second, through the

pumproom into the aft tanks of the system. At the discharge port, the

delicate parcel is discharged first, but not stripped. Any residue in

the tanks or pipelines is downgraded into the second parcel.

In dealing with loading sequences for shared systems, it is critical

to know the limiting cargo specification which is most subject to contamination.

If the limiting factor is colour, then the lightest parcel is the 'delicate'

one; if flash point, then the highest flash point product is delicate;

if lead, then the lowest lead content takes priority. Masters should

request guidance whenever they are in doubt regarding the sequence of

loading and/or discharging parcels in shared systems.

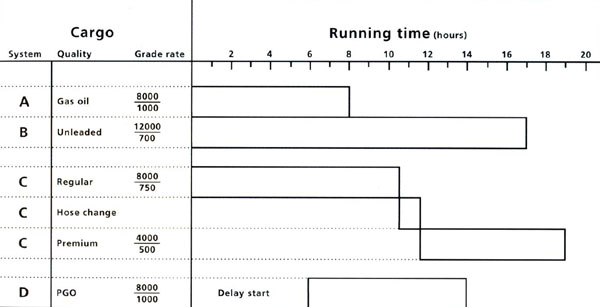

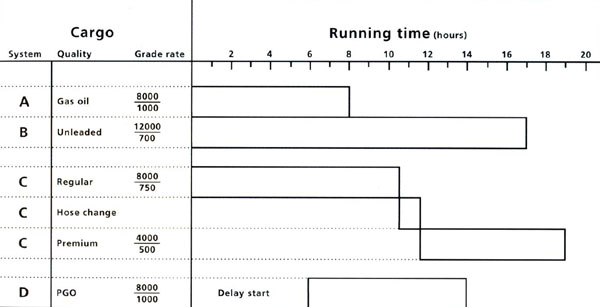

2.20.5 Critical path loading

Bar chart loading plan for a multi-grade clean

cargo, loading Regular should be started as soon as possible and Unleaded

shortly after. Gasoil and PGO should be started as convenient but

so that they do not finish at the same time as 'B' or 'C' grades.

Reductions in cargo loading times are possible through a careful examination

of all of the activities associated with the loading operation and identification

of the connected series of actions which will take the longest to accomplish.

When the longest series has been identified, effort is focused on starting

the first action as early as possible and subsequently reducing the

'delay time' between each critical action to a minimum. The technique

is most useful on vessels, such as parcel tankers, which are scheduled

to load a series of products. The critical path may be determined by

the order in which the cargoes must use the ship's piping system, or

it may result from the order they will be received through the shore

piping. Identification of the critical path requires full information

concerning:

Volumes of each parcel to be loaded.

The loading rate of each parcel.

The sequence parcels will follow each other through a shore line or ship's

piping system.

This information can be converted to bar chart form, with a horizontal

time axis and a vertical ship/shore piping axis and the loading of each

parcel plotted as a time bar against the piping system to be used. Once

the time bars have been plotted, it is relatively easy to identify the

sequence which will take the longest: the 'critical path'. When the

critical path has been identified, the ship's officers must focus on

ensuring that the tank, piping and manifold to be used for the first

parcel of the critical path series are fully prepared when the ship

arrives at the loading berth. The corresponding hose/loading arm must

be connected first and immediately after the tank is passed inspection

for loading, the first parcel of the critical path can be started. When

the first parcel is nearly finished loading, all preparations must be

complete to start the second parcel. With the critical path under control,

the remainder of the cargo can be attended to in an organised, but less

urgent fashion.

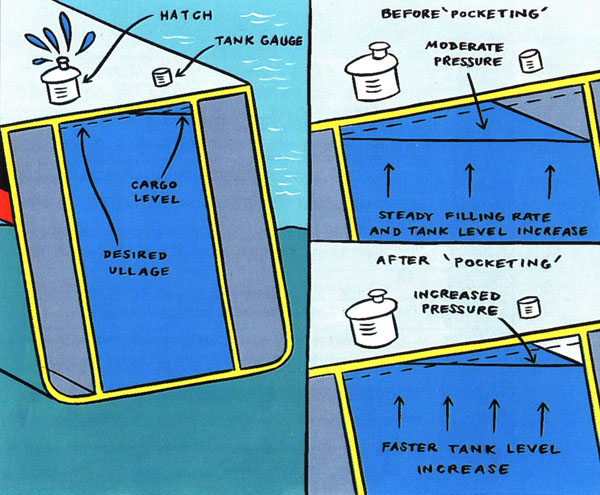

2.20.6 Ullage allowance

Company policy should dictate the minimum ullage to which the cargo

tanks may be filled. This should be a level at or below the 98% filled

level, or the level of the 'hi-hi' level alarm setting (if fitted).

To intelligently apply this guidance, the cargo watch officer must visualise

the location of the level sensors and level alarms in the tank and compare

this with the list or trim of the ship.

A very capable third officer once overfilled a centre tank in Houston.

The ship had a large port list. The mechanical gauge was located on

the starboard side of the centre tank and the tank lid, with open ullage

hatch, was located on the port side. Several centimetres before the

cargo reached to stop ullage on the tank gauge, a geyser of kerosene

erupted from the ullage hatch!

The cargo plan must allow for any expansion of the cargo to be expected

during the voyage. If there is insufficient ullage space, cargo expansion

due to increasing temperature can cause overflow with consequent oil

pollution, as well as possible structural damage.

If tank gauge is located at the high side of a

listed vessel an overflow may occur before final ullage is reached.

The same can occur if the ship has a large trim aft when topping off

and tank gauge is located forward in the tank.

A tank filling limit of 98% of capacity is generally considered adequate

for heated and non-heated grades alike. It allows room for cargo expansion

resulting from raising the product temperature by about 20 �C. However,

there are some occasions when an even greater ullage allowance may be

appropriate. The standard expansion allowance could be exceeded given

any one of the following conditions:

The cargo is loaded at a very low loading temperature, where an increase in

temperature of more than 20 �C can be expected on the voyage.

On voyages where exceptionally large variations in sea temperature are

to be expected.

On composite trading where un-heated products are stowed adjacent to heated

products.

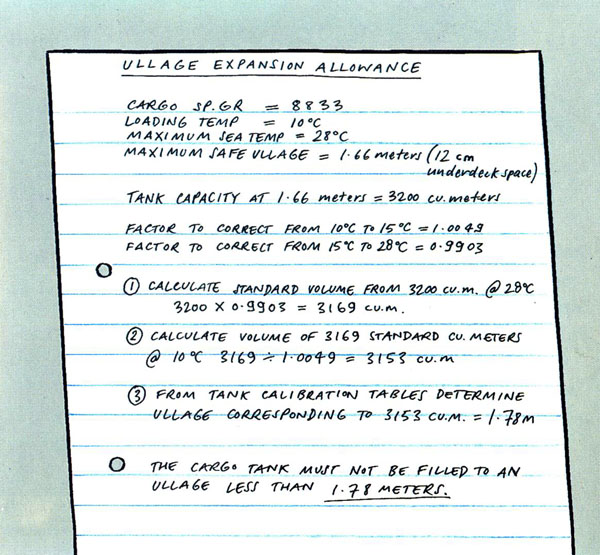

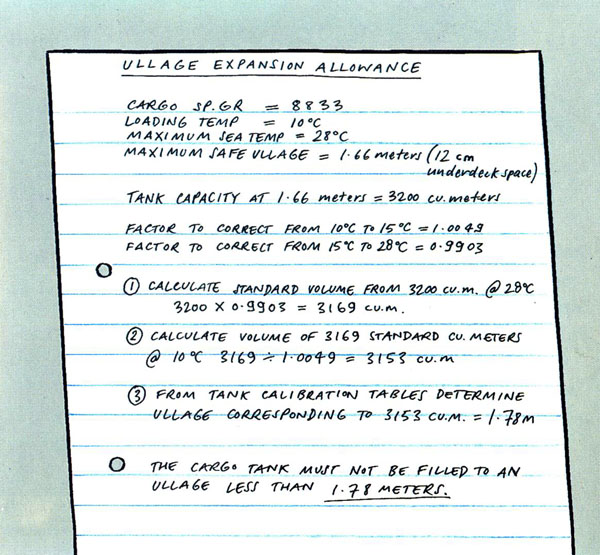

An example would be a product tanker loading product at 10 �C. The

sea temperature en route may approach 28 �C. If the tank volume

is 3200 cubic meters, what is the required ullage at the loading port

to ensure a 12 cm minimum under-deck ullage at the discharge port?

Where cargo temperature may increase during a

voyage the chief officer must calculate the necessary allowance for

cargo expansion.

In some cases, contraction of the cargo must be considered. Combination

carriers must maintain a minimum ullage in all tanks to prevent excessive

free surface and resulting unacceptable loss of transverse stability.

A combination carrier loading a warm cargo for delivery in a cold port

must fill each tank to a small enough ullage that all tanks remain above

the approved maximum ullage level when the cargo cools.

2.20.7 Written loading plan

When the chief officer has completed his review of all necessary factors

and checked his calculations, he prepares a written loading plan which

must include the following details:

Names of each grade of product or crude oil to be loaded and the quantity

of each.

Anticipated specific gravity and loading temperature of each grade of

cargo.

The cargo tank(s) each grade will be loaded into.

The pipeline system and loading path for each grade, including setting

of valves (identified by their unique identification numbers).

The sequence of loading of cargo grades.

The final ullage for each cargo tank.

The stand-by time required by the terminal for reducing loading rate or

stopping the cargo loading.

The anticipated departure draft.

Bunkers and ballast to be on board at departure.

Identification of all valves to be sealed closed before, during, or after

loading.

The maximum loading rates to be allowed and loading rate(s) expected with

the terminal.

Loading rate to be used for topping off tanks.

Special cargo procedures to be followed.

Special precautions with respect to moorings.

Equipment required (radios, ullage tapes, etc.).

Points in the loading when the chief officer is to be called or extra

manning is required.

Reference to standing orders for cargo operations.

Requirement that shore terminal regulations be read and signed by each

cargo watch officer.

2.20.8 Preparations for H2S

cargo

When the vessel is ordered to load sour crudes, the master must ensure that:

The vapour control system, including automatic tapes and vent lines,

is carefully inspected.

Self contained breathing apparatus is checked for condition and readiness

and the deck watch(es) are exercised in their use.

Pumproom lines, fittings and connections are checked for tightness and

any necessary repairs are completed before loading.

The portable H2S detector is in good operating condition. If sampling

tube testers are used, ensure that an adequate supply of test tubes

are on board.

|