|

3.23 CHANGING GRADES OF CARGO

When loading a multi-grade cargo, adequate standby notice is required

before stopping or finishing each grade. The cargo watch officer must

calculate when each grade will finish and give the shore terminal adequate

notice to stand by the pump controls and dock manifold valves. If the

final tank on a cargo grade is to be stopped at minimum ullage, the

shore should also be asked to reduce the loading rate to an agreed topping

off rate. As the tank approaches final ullage, the tank loading valve

should be closed one or two turns to verify that it is operating properly

and a member of the deck watch stationed at the applicable manifold

valve (unless it is remotely operated).

One or two centimetres before the final ullage is reached, the cargo

watch officer gives the order to stop the grade, indicating also the

manifold connection to be stopped. He instructs the deck watch to begin

slowly closing the manifold valve. By starting closure on the manifold

valve, the cargo officer is in a position to immediately reduce the

flow of oil into the ship, should the terminal fail to stop the cargo

flow as instructed. On multi-grade loadings the shore will occasionally

(though rarely), shut off the wrong grade of cargo. With the

manifold valve closed 2/3 to 2/4 the flow is significantly reduced,

allowing time to advise terminal personnel of the error and time to

stop the correct grade.

If the tank reaches the overflow point, the cargo officer must then

divert the flow to another tank, (even if it is a tank intended for

other cargo). Only as a last resort, where it is not possible for the

flow to be diverted elsewhere on the ship, should the manifold valve

be closed against the pressure of the shore pumps. The terminal's high-pressure

safety valve or high-pressure stop switch should then automatically

shut off the shore pump.

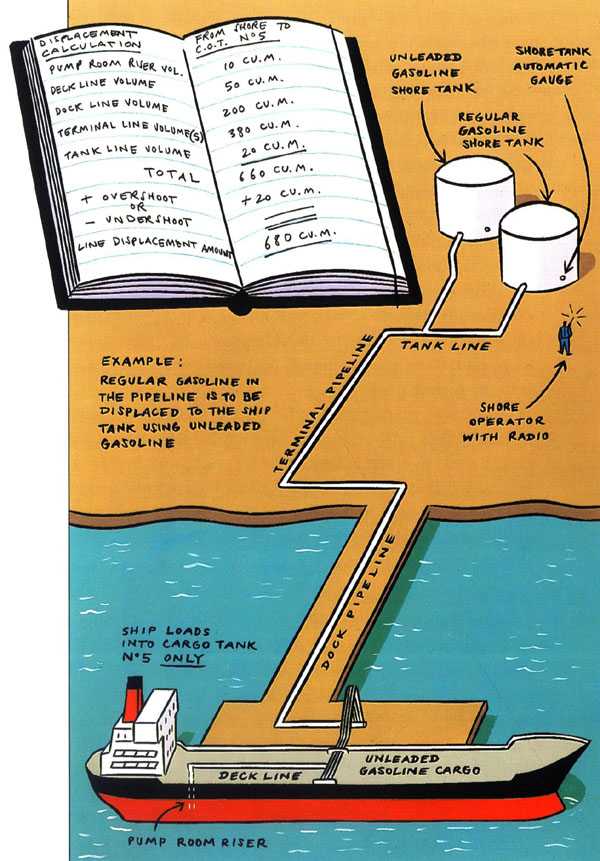

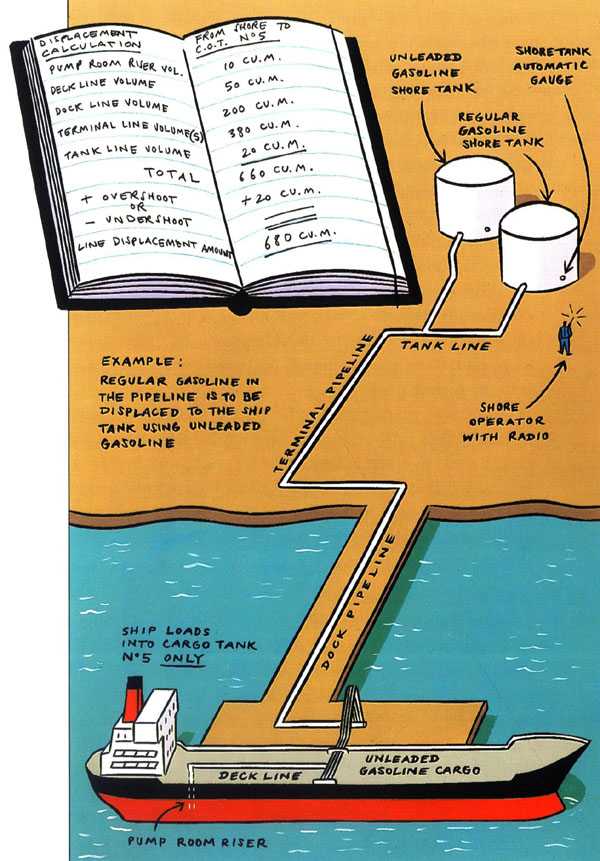

3.23.1 Line displacements

Between grades of cargo, the shore terminal may wish to displace the

shore pipeline system, pushing the previous pipeline contents onto the

ship or into another shore line and filling the line with the next cargo

grade to be loaded. If the displacement is done with shore lines only,

then the ship will not be involved. If the displacement is done onto

the ship, the amount to be displaced must be discussed and agreed during

the pre-loading conference. The chief officer must calculate a loading

stop ullage which provides the necessary cargo tank volume to receive

the line displacement.

This calculation should be re-checked by the cargo watch officer on

duty during the displacement. The tank ullage height (meters and centimetres),

required for the displacement volume should be calculated and added

to the final ullage. After the cargo is stopped for the displacement,

the watch officer subtracts the calculated height from the stop ullage

to determine the final ullage expected at the end of the displacement.

The line displacement calculation must include

all line volumes plus or minus an amount to ensure that the more sensitive

product is not contaminated.

In setting the quantity of the line displacement, the chief officer

should discuss the volume of the ship lines involved and whether they

should be added to the amount of the displacement. If the first grade

will contaminate the second grade (hut not the reverse), then the line

displacement should be slightly more than the total line volume, including

the ship pipelines. This will ensure that the entire loading line has

been displaced to the first cargo grade tank. If the second cargo grade

will contaminate the first grade, then the line displacement should

be as far as the dock manifold only, leaving the ship pipeline volume

as a buffer to protect the first grade.

When the displacement is started, it may be stopped either on reaching

a shore tank gauge reading (shore stop), or on the ship ullage reading

(ship stop). Regardless of which is indicated in the loading plan/night

orders, the cargo watch officer must call the stop when the ship's tank

reaches the designated ullage. Log the cargo stop, the displacement

start and the displacement stop (cargo grade finished), in the deck

logbook.

3.23.2 Draining and stripping pipelines

In some cases, the change of cargo grades on the ship will require the

removal of as much of the pipeline contents as possible, without using

a line displacement. This is required where the cargoes will cross-contaminate

one another and where no shore displacement is possible/scheduled. In

this case, the deck manifold valve is closed, the stripping pump suction

valves are aligned to the pipeline to be drained, and the pipeline manifold

vent valve is opened. The line contents are stripped, discharging to

the slop tank or other suitable tank until suction is lost. If possible

this process should be witnessed by the independent inspector. Record

the line draining process' in the deck logbook, including start and

stop guages in the receiving tank.

3.23.3 Changing hoses

Necessary hose changes during loading should be clearly indicated by

the shore and ship supervisors during the pre-loading conference and

written up in the loading plan and night orders. The cargo watch officer

should chalk the cargo grade on the second hose to be used and double

check both the correct manifold and the correct shore hose when the

hose change is made. If the dock watch personnel have changed and the

new watch personnel indicate that the hose change has been changed,

do not accept this advice until it is endorsed by the shore terminal

manager and provided to the vessel in writing. Carefully sample

the start of flow of the second cargo grade to verify that the correct

grade is being received.

When starting a new grade of cargo on a new hose connection, the loading

rate precautions indicated in section 3.16.2

for starting cargo must be observed.

|