|

3.24 TRIMMING THE SHIP

During the initial stages of loading, some trim and list is acceptable,

even unavoidable. However, the loading plan should be arranged so that

the ship is close to an even keel by the time the first set of tanks

is topped off and the list and trim should be minimised thereafter.

Excessive trim and/or list can negatively affect the topping off operation.

Trim and list must be limited to permit the ship to depart the berth

at any time during loading and to prevent grounding as the loading nears

completion.

3.24.1 Removing list

If the ship begins to list, the cargo watch officer must first determine

the cause of the list by checking the ullage readings in all off-centre

tanks. Some ships have a natural list, requiring more cargo to be put

into the opposite side to counteract it. List can be caused by asymmetrical

loading of wing tanks, mooring lines too tight, loading of fuel, excessive

free surface, or the vessel being aground. In most cases, uneven levels

in the wing cargo tanks is the cause. In this case, the cargo watch

officer must adjust the loading valves to reduce the flow of cargo to

the low side of the ship and/or increase the flow of cargo to the high

side.

If the list is not due to differential levels in wing tanks, then a

diligent search must be conducted, stopping the loading of cargo if

necessary, until the cause of the list is definitely determined.

3.24.2 Adjusting trim

As the loading operation nears completion, the ship should be close

to the desired final trim. When the second set of cargo tanks has been

topped off and the ship is loading the final set of 'trim tanks', the

chief officer should closely observe the forward and after draft of

the ship and recalculate the trim which will result from the final quantities

to be loaded. If this check indicates a final trim which is more or

less than desired, then an adjustment must be made.

Trim can be adjusted by:

Changing the final quantities to be loaded in each of the trim tanks.

Shifting cargo between tanks after loading is completed.

Shifting fuel between fuel tanks.

Adding water ballast.

The best method is to amend the loading plan, changing the trim tank

quantities to achieve the desired final trim.

The cargo watch officer should be instructed to confirm the chief officer's

trim calculations. In the absence of such instruction, he should do

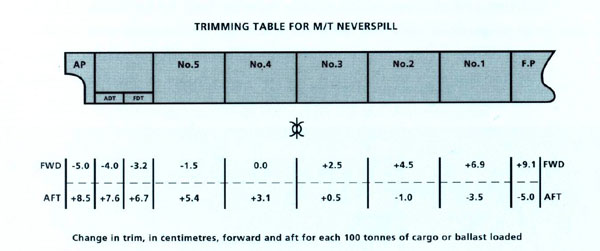

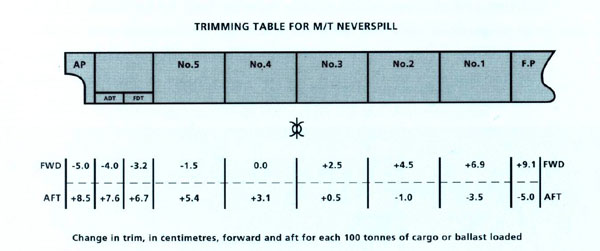

so on his own initiative. Use of the trimming table is the most convenient

way to do this. The officer determines the hundreds of tonnes to be

loaded in each trim tank, then multiplies it by the trimming factor

for the applicable tanks, adding (subtracting) the resulting figures

to (from), the forward and after drafts.

A rrimming table provides a rapid means of determining

the draft effect of each 100 tonnes loaded as the vessel approaches

full draft.

Shifting cargo between tanks after loading requires charterer's approval

(unless done at the loading port before gauging). If the cargo layout

and piping arrangement permit, cargo may be gravitated from full to

partially full or empty tanks after loading is completed to achieve

desired trim. Shifting cargo is not normally possible with multi-grade

cargoes.

Shifting of fuel for trim is only possible where the ship has forward

fuel tanks and will have sufficient fuel on board arriving at the discharge

port to maintain the desired trim.

Ballast can only be added to change trim when the ship will not be loaded

to its leadline mark with cargo alone.

During the final minutes of loading the chief officer will go onto the

dock and maintain a close watch on the trim and the loadline, indicating

to the cargo watch officer any adjustments of cargo flow to the trim

tanks to achieve the desired final trim. If the draft cannot be observed,

he should finish the loading by calculated volumes.

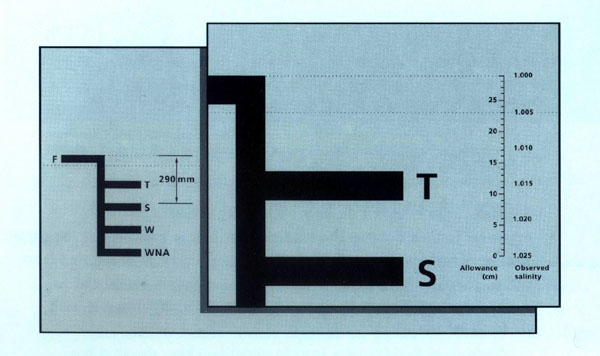

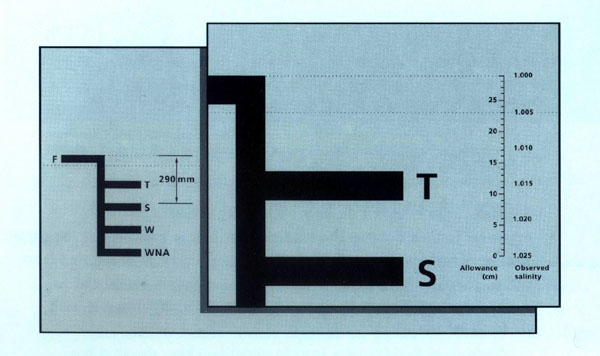

3.24.3 Salinity differential allowance

The tanker's loadline amidship must never be immersed below the applicable

level, regardless of the forward and aft drafts and the corresponding

'mean draft'. It is the amidship freeboard which is the controlling

factor whenever the ship is loaded 'to the marks'. The amidship marks

assume that the vessel is in pure salt water. That is rarely the case

in a loading berth, where the actual density of the water may be somewhat

less that the 1.025 nominal value for salt water. The portion of the

fresh water allowance that applies (salinity differential allowance,

or 'SDA'), is determined by first measuring the density (or salinity),

of the berth water. While the final cargo tanks are filling, a clean

bucket on a heaving line should be used to take a water sample from

the berth. The specific gravity of the sample must be measured using

a calibrated hydrometer.

For this Panamax tanker - an observed salinity

of 1.005 indicates that the summer loadline may be immersed 23 cm

on departure.

The SDA to be applied to the limiting loadline is calculated by the

fraction:

SDA = (1.025 - observed density) x fresh water allowance / 0.025

If the tanker has a fresh water allowance of 50 cm and the berth water

density measurement is 1.020, then the ship can load so that the applicable

loadline is immersed by

(1.025 - 1.020) x 50 / 0.025 = 50/5 = 10 cm

10 cm below its upper edge.

|