|

3.31 SPILLS AND OVERFLOWS

Good planning and careful attention to the basic precautions of safe

loading will prevent most spills or tank overflows from occurring. However,

there will occasionally be errors or mechanical failures which cause

cargo to escape onto the deck, into the pumproom, or into the sea. The

size of the spill will be directly related to the inattention of the

cargo watch. If the pumproom is not being carefully monitored, large

areas of deck are left unobserved, or the cargo watch officer is absent

from the CCR/deck for an extended period, then there is an excellent

opportunity for a large spill.

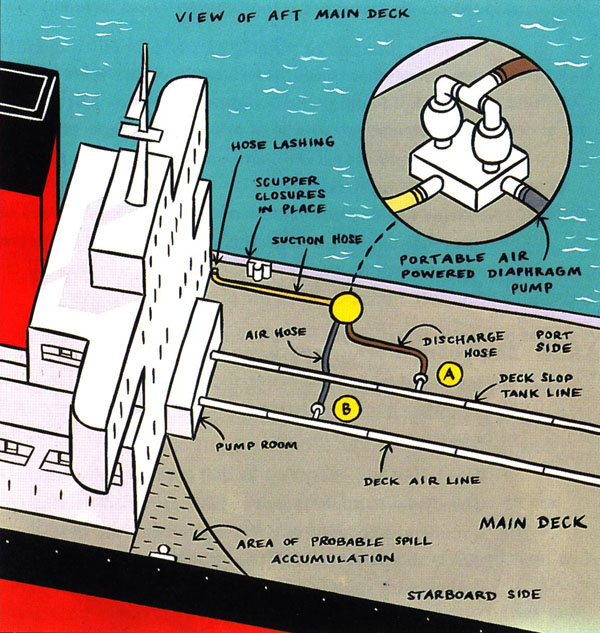

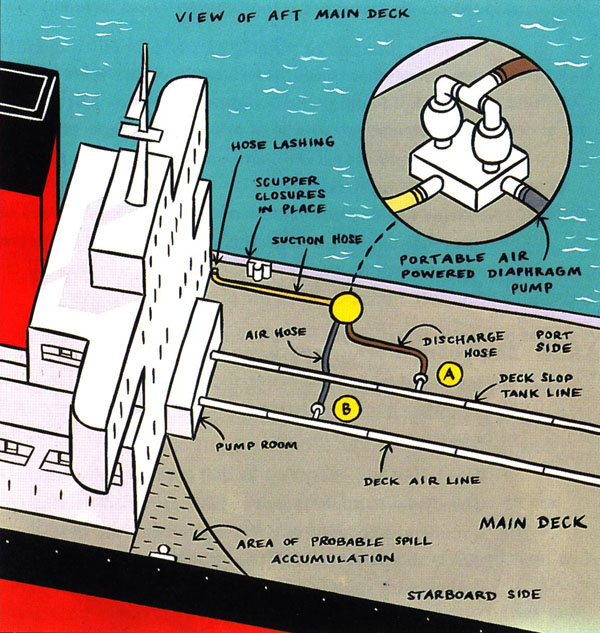

3.31.1 Spill containment installations

Some spill containment preparations begin on the drawing board of the

tanker designer, or must be added by conscientious owners if absent

from the original design:

- Gutter bars of sufficient height must be provided along the main deck

gunwale, separating the main deck from the aft deck and around the aft

deck (in event of a spill while fuelling).

- The gutter bar openings and all deck scuppers must be designed so

that they can be readily closed oil tight and the closure hardware or

devices must be both easy to use and durable. Wooden plug or sliding

plate and cement closures are not effective. Expanding rubber plugs

are very effective, convenient and durable.

Portable air-powered pumps should be fully rigged

before cargo operations begins. Lash the suction hose in position

where spilled oil will accumulate. In case of a deck spill, open valve

A, then valve B.

- Spill containment tanks can be provided in the original design of

the ship, or added as a modification. They should be located at the

aft main deck on each side and fitted with a sluice opening so that

accumulations of oil can be drained into them by opening a single valve.

This valve should be left open at all times while the ship is loading

or discharging in fair weather. Transfer fittings and piping must be

provided to permit pumping of any accumulations to the slop tank.

- Provide convenient connections for compressed air and deck slop line

fittings for air operated pumps to be used to recover spilled oil from

the deck.

3.31.2 Management initiatives

Many of the initiatives needed to prevent and control spills are a shipowner's

or manager's responsibility. These include:

- Provide a program of training aids to properly prepare the crew to

prevent spills or to deal with overflows and spills when they occur.

- Provide spill containment and recovery materials and equipment.

- Ensure that regular training in oil spill counter measures is regularly

performed on board and records maintained (per OPA-90 requirements).

- Provide the ship with an effective oil spill contingency plan and

ensure that agents, contractors and owner's local representatives regularly

call on the ship to discuss their roles in spill response.

- Conduct annual drills of the plan.

3.31.3 Shipboard precautionary measures

On board the tanker, the materials, equipment and plans provided by

the owner must be effectively used. Oil spill prevention measures to

be taken on board include:

- Regular training exercises in spill counter measures including when/how

to apply foam to spills, use of adsorbents and skimmers, rigging of

recovery equipment, use of spill containment

tanks, and personnel health and safety considerations when dealing with

spills.

- Verification/testing that all cargo deck drains are tightly closed

before loading begins.

- Rigging oil recovery pumps at natural spill collection points on deck

before loading begins.

- Maintaining spill containment tank sluice valves open while loading

in fair weather and closed during periods of heavy rain.

- Instructing deck watch personnel in the proper method of decanting

rain water accumulations from the deck.

- Regular inspections of the pumproom(s), all cargo deck areas and all

compartments/spaces where oil cargo could possibly leak into during

loading.

- Strict adherence to all precautions and procedures while topping off

cargo tanks.

All tanker officers should remember that only 10-15% of spilled oil

is ever recovered from the water. The best recovery technique is

still prevention! The one precaution which will contribute most

to prevention is strict adherence by all cargo watch personnel to the

simple rule:

When in doubt ... shut down!

3.31.4 First actions in the event of a spill

Should the unhappy event of a spill occur, the cargo watch officer must

have a checklist at hand directing his initial response until the master

or chief officer arrive to assume command. The following are some essential

initiatives. The order of execution is provisional, circumstances and

the details of the vessel's contingency plan may dictate a preferred

sequence or assign some of these actions to others who have been notified

by the ship:

- Stop loading cargo; notify the terminal to shut down and the reason.

- Open an empty tank (if available) on the same system to reduce pressure

on the tank/line which is leaking cargo.

- Sound the spill alarm on the ship, or announce it over the PA system.

All open lights should be secured when this is heard.

- Instruct the engineering watch to secure accommodation and engine

room intake fans as necessary.

- Direct the deck watch to open deck containment tanks (if not already

open), or start spill recovery pumps.

- Warn any craft alongside, instructing them to secure all sources of

ignition.

- Start or request the engine room to start the fire pump (this may

be automatic on sounding of spill alarm).

- Implement the vessel's oil spill contingency plan, including notification

of coast guard, owners oil spill response contractor, and others as

required.

- If master or chief officer are not on board, initiate the necessary

telephone calls to advise them of the situation.

- Advise the vessel's agent or owner's local representative; advising

them to notify necessary officials and mobilise the clean up contractor

(if required).

- Notify the port vessel traffic service or harbour master by VHF radio.

- Advise the master/chief officer of the grade of cargo spilled and

the approximate quantity. The master's responsibilities normally include

notification of owners, technical managers, P&I Club representatives.

- Maintain an accurate record of the events and times of response actions,

but do not make any log entries until reviewed by the master.

- Ensure that crew members dealing with the spill have equipped themselves

with the proper personal protective equipment.

- No dispersants or chemical 'herders' should be used without prior

approval of local authorities.

Logbook entries and reports made following a spill incident must be

absolutely factual and truthful. An officer who has been conducting

his watch properly has little to fear from a spill inquiry and may be

confident that the facts will support him. An officer who attempts to

conceal some neglect will inevitably have his dishonesty discovered

and will be in worse trouble. The more honest the disclosure of events

and causes of a spill, the faster the event will be investigated and

disappear into the archives and the quicker the participants can resume

their normal activities.

3.31.5 Handling dangerous spills on board

Occasionally a cargo spill will be particularly dangerous because of

the low flash point and high vapour pressure of the cargo. Such cargoes

would include condensates, naphtha and gasolines. These spills are dangerous

because of the fire danger created by their uncontrolled release of

flammable vapour in confined spaces or on the open deck.

If these cargoes are spilled into the pumproom, a layer of fire fighting

foam should be applied to the pumproom bilges before any other measures

are taken. The foam will reduce the release of explosive vapour to the

atmosphere, cut off oxygen needed or combustion, and permit cargo recovery

measures to be taken in more safety.

Foam may also be applied to low flash products spilled on the main deck,

but care must be taken to avoid using so much foam or water that the

gasoline is washed over the containment.

In some cases where foam cannot be readily applied and the danger of

ignition is great, it may be better to wash the spilled cargo overboard

before it can ignite. Such a decision should be made only by the master

after carefully considering the risk of fire against the certainty of

a pollution citation.

3.31.6 Hull leaks

If cargo is seen entering the water through a hull leak, then in addition

to the actions in section 3.31.4, the cargo watch officer should immediately

take action to transfer cargo from the leaking tank. Cargo can be gravitated

or pumped to another ship's tank. If there is no available space in

the ship's cargo or slop tanks, then the cargo must be pumped ashore

as quickly as possible. These actions must not be delayed by concerns

for cargo quality or cargo contamination.

3.31.7 Master's actions

The master must be fully trained and have all necessary information,

resources and authority to respond to an oil spill by doing the following:

- Evaluate and properly assess the spill.

- Make the necessary notifications. Use IMO Resolution 680(17) content

format for notifications transmitted by telex or radio.

- Direct or cause all necessary actions to minimise, contain, or reduce

the escape of oil.

- Activate the vessel and owners 'oil spill contingency plan'.

- Request necessary outside assistance (clean up contractor).

- Maintain detailed action and event logs, having in mind the information

which will be required for spill reports.

- Follow up all actions previously ordered to ensure that they are being

properly carried out.

- Cause samples to be taken and properly labelled and stored.

- Review media training received and prepare to appropriately respond

to their questions.

|