|

2.2 CLEAN BALLAST TANK SYSTEMS AND PROCEDURES

Tank ships which are not equipped with segregated ballast tanks (SBT)

may use their cargo system piping to take ballast into tanks reserved

from carrying cargo. These reserved, clean, ballast tanks (CBT), are

either original cargo tanks set aside for this purpose, or specially

constructed tanks. The original purpose of the CBT concept was to provide

an interim step between the earlier system of placing ballast in cargo

tanks, and the ultimate goal of requiring SBT for all tankers. CBT was

intended to reduce creation of oil and water mixtures on ships which:

Are not provided with SBT, or

Cannot COW because they do not carry crude oil.

Some CBT tankers have a pump and line sections reserved for ballast. The

ballast operation for these ships are a combination of CBT and SBT procedures.

The CBT filling and discharge procedures involve several opportunities

for a pollution incident if they are not conducted exactly according to

approved procedures.

Case history

In late 1990 a 57,000 DWT product/crude carrier arrived in Boston to off-load

cargo. On arrival the ship requested a United States Coast Guard tank

vessel examination letter. The previous letter has been withdrawn after

a Coast Guard examination at Philadelphia revealed several deficiencies.

That action was followed by two oil spills, after which the ship's crew

was changed.

In Boston five of the vessel's seven ballast tanks were found contaminated

with oil. In addition, ballast was being carried in a centre tank, contrary

to the IOPP certificate which listed the corresponding wing tanks for

CBT. The ship's chief engineer confessed that he had pumped engine room

bilges into the same centre tank. Further inspections revealed undocumented

changes to the ballast system and inoperative ballast valves. Other ship

systems were found in a similar state of disarray and disrepair.

The vessel was denied entry into the port of Boston. The classifications

society withdrew the ship's IOPP and SOLAS certificates. Local news media

featured the vessel and its owners and operators on the evening news.

The US Coast Guard began assessment of civil penalties for violations

of MARPOL ANNEX I. The ship was issued a temporary certificate to depart

on a one-way voyage to off-load its cargo, and then proceed directly to

shipyard.

Case analysis

To say that the condition of this ship in the above case demonstrates

deplorable management would be an understatement. Like the worst absentee

landlords, the owners had obviously let the vessel deteriorate until it

was a hazard to its crew and to the environment. It is possible that the

vessel was being managed under a technical management contract instead

of directly by the owner. Such an arrangement would not excuse the owner

from his obligation to know the condition of his ship and correct significant

defects.

The most difficult position in this case is that of the master and crew.

They find themselves employed on a sub-standard ship, in a foreign port,

caught between clear and specific rules and requirements and an owner

who refuses to provide the means for compliance. What should they do?

The only thing to do in a case like this is to proceed as far as the condition

of the vessel permits, then stop and advise the owner that operations

cannot proceed because of the defects or conditions noted. The worst the

owner can do is replace the crew. In this case, the vessel's officer's

attempted to proceed with the defects unrepaired. For their efforts, they

will have personal records in the US Coast Guard computer files, they

will be reported to the authority which issued their licenses, and they

were replaced!

Something every ship's officer should understand is that no owner will

support him if he has broken the law. Some officers bend or break pollution

regulations because they think the savings of time or cost will be appreciated

by the owner. In truth, any good owner would be appaled by such actions.

The fines and penalties to which the owner may be exposed by the infractions

of some well-meaning crew member far outweigh any possible saving. Conscientious

owners expect that their crews will follow both laws and company policies

with equal diligence as the best way of safeguarding the owner's interests.

2.2.1 Clean ballast systems

The requirements for CBT systems and CBT operations are detailed and

specific. They are set forth in IMO Resolution A.495 (XII) of 1981.

Unlike segregated ballast tank (SBT), systems, clean ballast tank ships

do not have complete separation of the ballast and cargo systems. A

CBT ship uses some of its cargo piping, pumps, and valves to load and

discharge ballast from the clean ballast tanks. However, it has become

an apparently permanent fixture of older tankers, giving them an extended

economic life and continued opportunities to cause operational pollution.

The CBT system has added complexity to existing tanker operations. Using

it properly requires careful study of the particular system, close attention

to the procedures for conducting each step of CBT operation, and time.

The most difficult CBT operation is ballasting at the discharge port.

2.2.2 CBT operations in the discharge port

All CBT operations begin by flushing cargo pipelines with water from

the clean ballast tanks. In the discharge port, where the ship arrived

full of cargo, the CBT tanks must either contain retained ballast for

flushing, or flushing water must be added 'over the top' while the ship

is discharging. If adequate ballast for flushing was not retained when

departing the loading port, it may be added in the discharge port using

the ship's fire main system, bilge and ballast system, or through some

other means. The ballast tanks must contain an amount equal to either

ten times the volume of the piping they are required to flush, or enough

ballast water to prevent vortexing until the piping has been run full

of water. This amount will be specified in the ship's CBT manual.

2.2.3 CBT manual

Each tank vessel which operates in the CBT mode is required to have

a CBT operations manual specifically prepared for it. The required content

and format of this manual is prescribed in the IMO publication Dedicated

clean ballast tanks, revised specifications for oil tankers with dedicated

clean ballast tanks and standard format for the dedicated clean ballast

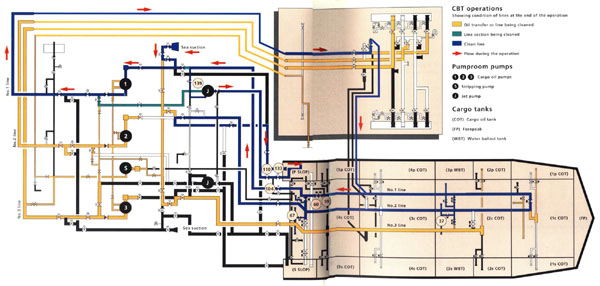

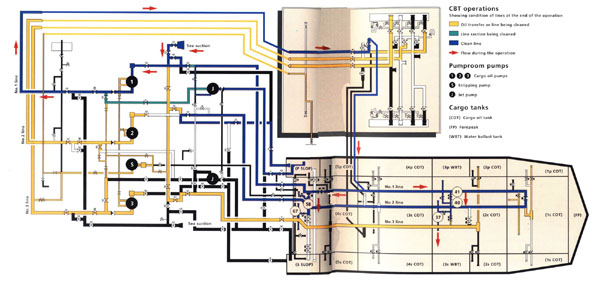

tank operation manual. An example CBT operation manual and diagram

are included in the IMO booklet. Despite the IMO efforts to provide

clear direction for CBT operations, many vessels do not conduct their

CBT operations properly.

The IMO guidelines should be recognised as the minimum written procedures

an operator should provide to insure correct ballast operations. It

is recommended therefore that managements should take care to prepare

scrupulously detailed and illustrated instructions for each CBT operation.

The instructions should include the following:

Presentation of the CBT operations by type, ie:

Loading port operations.

Extra or heavy weather ballast.

Discharge port operations.

Other operations.

Identification of all CBT valves by number.

Presentation of CBT operations in single steps.

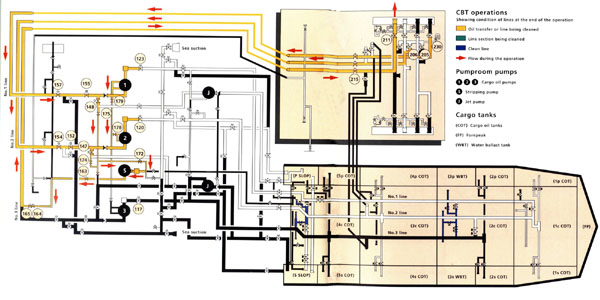

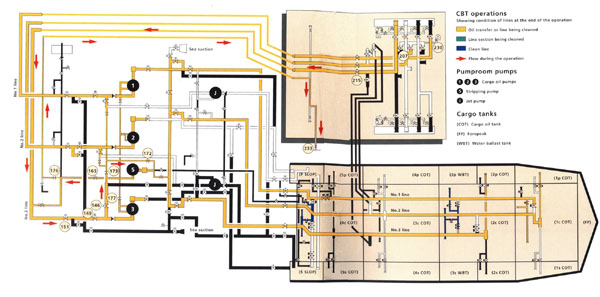

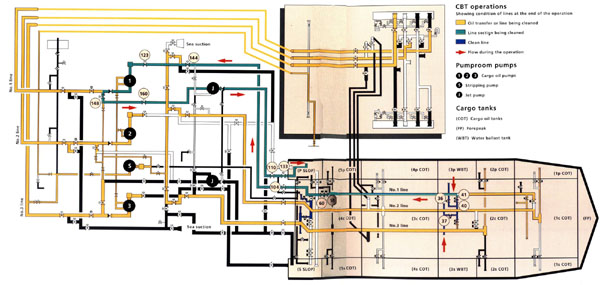

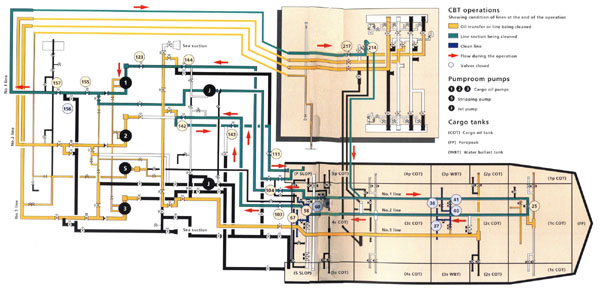

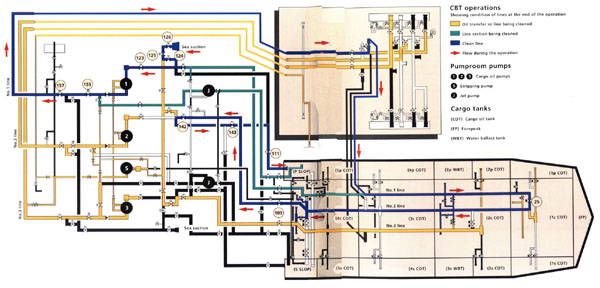

Illustration of each step with a colour-coded line diagram.

Checklists for each CBT operation.

Instructions for sealing, lashing, or locking critical valves

which must remain closed.

The following is an example CBT operation at the discharge port. The

system plan and valve numbering is the same as contained in the IMO

Dedicated clean ballast tanks guide (1982 edition, reprinted

1987). The instructions have been presented in a step by step fashion,

with illustration for each.

It is assumed that the clean ballast tanks contain sufficient water

to perform the preparatory flushing operations described. If sufficient

flushing water is not in the tanks at the start of the discharge, it

must be transferred to them using the ship's fire main and hoses, or

by some other means.

Readers will note in some places that the instructions call for the

crew to 'close all valves', and then instruct that a valve just closed

is to be opened again. This is intentional. Few tanker contaminations

or pollution incidents have ever been caused by a valve improperly left

closed. Pollution and contaminations are caused by valves incorrectly

left open! Any valve not in immediate use should always be in a closed

position. Where a complex transfer operation is to be conducted, especially

as in the case of flushing pipelines, the only sure way to properly

set the valves is to close all of the valves in the system, then open

those required for the next step.

CBT operations after cargo discharge is complete:

-

Complete the discharge of all cargo from the ship's tanks. Strip

pumproom risers and deck discharge lines ashore:

- Thoroughly strip the No.l and No.2 pumproom cargo risers and the

deck discharge lines into the No.3 cargo line and ashore via the No.3

port manifold. (This step is essential to preventing harbour pollution

when the sea chest valve is opened to provide ballast water.)

The following steps are required:

1 Open valves:

148 (No.1 pump discharge to jet pump), 175 (stripping

suction to No.1 line),

179 (No.1 cargo pump stripping suction), 172

(stripping pump suction), 147 (No.2 pump discharge to jet pump), 174

(stripping pump suction to No.2 line),

178 (No.2 cargo pump stripping

suction), 163 (stripping pump discharge valve), 164, 165 (stripping

discharge to No.3 line),

205 (No.1 line manifold vent valve),

206 (No.2 line manifold vent valve), 230 (manifold vents inlet valve),

(Valves 152, 154, 155, 157, 215 and 211 remain open from cargo discharge.)

2 Close cargo pump suction valves 117, 120 and 123.

3 Start the stripping pump. Continue

to strip lines until pump loses suction.

4 Close valve 172.

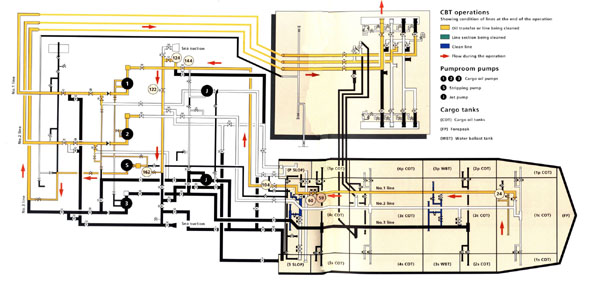

Strip No. 1 bottom line ashore:

5 Open valves:

162 (stripping suction to pumproom suction crossover

line),

122 (sea suction crossover block valve),

124 (No.1 pump suction crossover valve),

144 (No.1 line pumproom block valve),

104 (No.1 line pumproom bulkhead valve),

60, 59 (No.1 line block valves).

6 Start stripping pump.

When stripping pump has developed a suction vacuum

on No.l line, open valve 24 (No.1 centre tank main suction valve).

The

vacuum in the line will drain the length of the No.l line and the No.1

deck drop without allowing any cargo to fall back into the tank.

7 When stripping pump loses suction,

stop the pump.

Strip No.2 bottom line ashore:

8 Close valve 122.

9 Open valves:

121 (pumproom crossover to No.2 cargo pump suction),

142 (No.2 cargo pump block valve),

103 (No.2 line pumproom bulkhead valve).

10 Start stripping pump.

When a vacuum is indicated on No.2 line open valve:

26 (No.1 port cargo tank main suction valve).

11 When the stripping pump loses

suction, stop the pump.

12 Close valve 26.

Strip No.3 bottom line ashore:

13 Open valves:

119 (sea suction crossover block valve),

118 (pumproom suction crossover to No.3 line),

141 (No.3 pump suction block valve),

102 (No.3 line pumproom bulkhead valve).

14 Start the stripping pump.

When a vacuum is indicated on the No.3 line open

valve: 32 (No.2 port cargo tank main suction valve).

15 When stripping suction is lost,

stop the pump.

16 Close all valves.

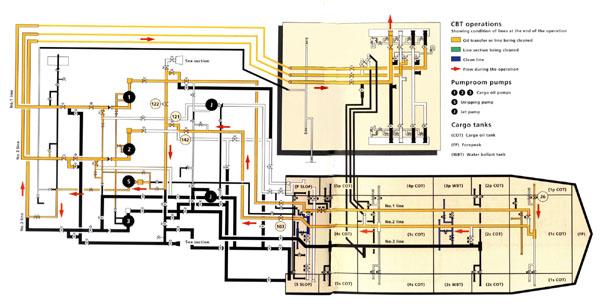

3. Strip the No.3 pumproom riser and deck line to the

starboard slop tank:

1 Open valves: 173

(No.3 to jet pump supply line stripper suction),

172 (stripping pump suction valve), 163 (stripping pump discharge valve),

176 (stripping pumproom riser valve), 233 (drop valve to starboard slop

tank),

146 (No.3 pump discharge to No.3 jet pump valve),

177 (No.3 cargo pump stripping suction), 149 (No.3 pump discharge valve),

151 (No.3 line pumproom riser), 215 (No.3 deck line block valve), 207

(No.3 line manifold vent valve), 230 (manifold vents inlet valve).

2 Start stripping pump. When

pump loses suction, stop stripping and close all valves.

All residual cargo has now been removed from the ship's pipelines. The

next step prepares the lines for receiving clean ballast by flushing them

with retained ballast water from the CBT tanks. 4.

Prime the No.l cargo pump

1 Open valves:

123 (No.1 pump suction valve),

144 (No.1 line pumproom block valve),

104 (No.1 line pumproom bulkhead valve),

60, 59 (No.1 line, block valves),

41, 40 (No.l to No.3 lines crossover block valves),

36 (No.2 centre rank stripping suction valve).

2 After one minute: close

valve 36 (No.2 centre stripping suction), open valve 37 (No.2 centre

tank main suction valve).

3 Wait thirty minutes

(to allow the water to remove oil clingage from

the pipeline walls).

4 Vent pump casing to insure

pump is primed.

5. Flush No.3 centre tank branch line and

No.1 main cargo line to port slop tank from No.2 centre tank:

1 Open valves:

148 (supply to No.1 jet pump), 160 (No.1 jet pump

block valve), 110 (No.1 jet pump bulkhead valve), 133 (port slop tank

fill valve).

2 Start No.1 pump and flush from

No.2 centre tank main suction, via No.1 line, and discharging through

the No.1 jet pump to the port slop tank.

3 Flush for three minutes.

4 Stop the No.1 pump.

5 Close valves:

37 (No.2 centre tank main suction valve), 40,

41 (No.1 line to No.3 line crossover), 59, 60 (No.1 line, block valves).

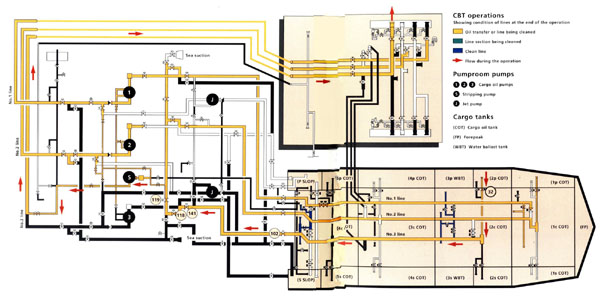

6. Flush the No.1 pumproom riser, deck line, and

deck drop line from No.4 centre (ballast tank) to the starboard slop tank

via No.2 line:

1 Valves 104, 144, 123 remain open

from the previous operation.

2 Open valves:

67 (No.4 centre ballast tank main suction valve),

58 (No.l line to No.4 centre tank suction block),

155 (No.1 pump discharge valve),

157 (No.1 line pumproom riser valve),

217 (No.1 line deck block valve},

214 (No.1 line deck drop valve),

25 (No.1 line to No.2 line crossover valve),

103 (No.2 line pumproom bulkhead valve),

142 (No.1 pump suction block valve),

143 (No.2 line crossover valve to port slop tank suction/fill line),

111 (port slop tank suction/fill valve).

(Note: valves 40, 41, 36, 37, 59, 60 and 156 are closed for this operation.)

3 Start No.1 pump and flush at

slow speed for thirty minutes from No.4 centre ballast tank, via pumproom

risers, deck line, deck drop, No.2 line and pumproom into port slop

tank.

4 Stop No.1 pump.

5 Close valves:

104 (No.1 line pumproom bulkhead valve), 144 (No.1

pump suction block valve).

7. Flush the ballasting line (No. 1 line) to the port slop tank from

the sea:

1 Open valves:

125 (port sea suction block valve),

124 (No.1 line to pumproom crossover valve).

2 Start No.1 pump.

3 Open valve 126 (port sea suction).

4 Flush from sea via pumproom

riser, deck line, deck drop No.l and No.2 bottom lines to port slop

tank.

5 Stop the No.1 pump.

6 Close valves:

25 (No.1 line to No.2 line crossover valve), 103

(No.2 line pumproom bulkhead valve),

142 (No.2 pump suction block valve),

143 (No.2 line suction/fill to slop tanks), 111 (port slop tank suction

fill valve).

It should be noted that step 7 opposite is closely

related to the old practice of taking ballast into cargo tanks. If the

line flushing operation has not been properly conducted it also offers

the same opportunity to create a pollution incident. Since the flushing

operation is to a slop tank containing a quantity of water, there is

a possibility of back flow when the sea suction valve is opened. The

starting of the pump must be closely coordinated with the opening of

the sea valve to minimise the opportunity for outflow through the sea

suction.

7 Open valves:

59, 60 (No.1 line block valves),

104 (No.1 line pumproom bulkhead valve),

139 (No.1 line to pumproom suction crossover valve),

110 (jet pump discharge to slop and ballast tanks),

133 (port slop tank fill valve).

8 Start the No.1 pump.

9 Flush from sea via No.1 pumproom

riser, deck line, deck drop, pumproom suction line, port jet pump, to

port slop tank. Flush for three minutes.

10 Stop No.1 pump.

11 Close valves 104, 139, 110,

133.

12 Open valves: 37

(No.1 centre tank main suction valve), 67 (No.4 centre ballast tank

main suction valve).

Inspect No.2 centre and No.4 centre ballast tanks for presence of oil

visually and with a hydrocarbon vapour tester, if oil is present tanks

must be emptied and ' washed to slop tank and flushing sequence repeated.

If tanks are free of oil, ballasting may proceed.

8. Ballast No.2 centre tank and No.4 centre tank

from sea via No.1 line:

1 Open valves:

58 (No. line to No.4 centre tank suction and fill),

67 (No.4 centre tank suction and fill valve), 41, 40 (No.1 line to

No.2 centre tank block valves), 37 (No.2 centre tank suction and fill

valve),

2 Start No.1 pump.

Ballast CBT tanks as directed.

2.2.4 MANAGEMENT CONTRIBUTION TO POLLUTION-FREE

CBT OPERATIONS

The amount of detail involved in the CBT procedures (see section 2.2.3),

clearly illustrates the complexity of CBT operations and the necessity

for adequately trained crews using clear, step-by-step operating procedures

and checklists. Also obvious is the number of opportunities for something

to go wrong! Despite the original intention for CBT to be an interim

measure, it remains a 'permanent' ballasting procedure for many ships.

For those vessels, management must insure that 'foolproof CBT directions

are provided to the crew. Carefully prepared CBT directives illustrates

management due diligence. If the crew uses photo copies of the procedures

as a checklist, and enters the date and time when each step was performed,

then due diligence in the performance of the procedures can be proven.

If a pollution does occur, evidence provided by the procedures and the

completed checklist will help to minimise any penalty.

2.2.5 Ballast records

All details of ballasting operations must be recorded in the oil record

book. Dirty ballast operations are also recorded in the port log. The

deck log book is used to record:

Dirty ballast taken on in port.

Dirty ballast taken on in river or sea.

Clean ballast taken on.

Dirty ballast discharged at sea.

Oil record book entry for CBT ranker.

All entries must include the times, tanks, and pipelines used for

the ballasting operations, and the vessel's positions at the time of

ballasting.

|