|

2.9 TANK WASHING PLAN

The requirements for tank washing during the ballast voyage are determined

primarily by the cargo orders for the next voyage and the cargo previously

carried. When the prior cargo is compatible with the next cargo to be

carried, tank washing may not be required. At the other extreme, if

a clean product voyage follows a black oil cargo then preparation may

require extensive tank washing, cleaning and even drying before the

tank is ready for the next loading. Other reasons for tank washing include

preparations for clean ballast, maintenance cleaning (to prevent sludge

accumulation), leak detection, tank or piping repairs and shipyard cleaning.

Between 1/4 and 1/3 of the ship's tanks may be washed for the reasons

above. In laying out his tank cleaning plan the chief officer considers

cargo requirements, ballast, repairs and maintenance. The most efficient

program is one which cleans as many tanks as possible for more than

one purpose. For example, if the chief officer has the choice of cleaning

and de-scaling one of two tanks for a cargo change, one of which has

been recently inspected, he should clean the other tank so that it may

be inspected during the de-scaling operation. Tanks which were crude

oil washed require water washing before they can be filled with 'clean'

ballast.

2.9.1 Tank preparation matrix and instructions

A time charterer may be responsible to the cargo owner for the adequate

preparation of the ship's tanks to receive cargo, but the owners and

master are ultimately responsible to charterer for the condition of

the ship's tanks for each voyage. The most important tool for setting

out the tank washing program is the tank washing matrix or cargo change

matrix. The tank washing matrix is a grid diagram with the 'previous

cargoes' arranged in horizontal rows and the 'next cargoes' listed as

vertical columns. By finding the intersection between the column corresponding

to the last cargo carried and the row headed by the next cargo to be

loaded, the chief officer can determine the tank preparation requirements.

Tank washing matrices should be provided for both coated and un-coated

tanks, as the required preparation is somewhat different. Coated tanks

with coating failure of more than 10% of the total surface should be

considered and washed as un-coated tanks.

This table is an example of a cargo tank preparation

matrix for use on clean product tankers. The recommendations are examples

only, and should not be used for guidance when owner's or charterer's

tank cleaning instructions are available.

The origin of a tank preparation matrix is the amount of maximum allowable

contamination between products which can be permitted while maintaining

product quality. Cross contamination between products can affect a number

of product criteria such as:

Colour, octane, density, bromine number, lead, sediment, cloud point,

flash point, vapour pressure, viscosity, gum, sulphur, thermal stability,

odour, pour point, smoke point, carbon content, final boiling point,

initial boiling point, water separator index, mercaptan.

It would be difficult for a chief officer to evaluate each of these

criteria when changing cargoes. Owner's have done this for him by preparing

standard tank washing matrices.

The levels of preparation indicated may include:

No cleaning required

Drain lines and pumps

Hot water machine wash

Ventilate tanks

Remove all sludge and scale

Mop and ventilate tank

Number of washing cycles |

Bottom flush and strip dry

Cold water machine wash

Fresh water rinse

Gas free tanks

Remove all free water

Cleaning impractical

Number of washing hours |

The table above is an example of a cargo tank preparation

matrix for use on black oil tankers. The recommendations are examples

only, and should not be used for guidance when the owner's or charterer's

tank cleaning instructions are available.

The required preparations may include any one, or a combination of

the above procedures. The most stringent preparations are required for

refined products, but some mixtures of crude oils can be equally troublesome.

Some combinations of crude oils can form nearly impervious residues

and some crude oils with special properties, such as nil sulphur, can

be contaminated by other crude oil residues.

In every case where a tanker is instructed to load a cargo different

from the previous cargo, cleaning instructions must be provided with

the orders. The instructions may be a simple as 'charterer's minimum

cleaning requirements to be completed', thereby referring the master

to the charterer's printed instructions and a tank cleaning matrix for

tank preparation. Alternatively, the preparation may be a page of detailed

steps. If the master or chief officer has any question about the necessary

tank preparation, then the owners must be consulted for clarification.

Example tank preparation matrices are included in this section. It is

important that the master and chief officer follow the procedures required

by the owner/charterer for tank cleaning. If a special circumstance

arises which is not covered by the instructions, or which requires special

measures, then the situation must be communicated with owners/charterers

and the tank(s) cleaned according to their reply.

Tank inspections at the loading port may be performed by independent

inspectors (representing the charterer or cargo owner), or by terminal

inspectors. Masters should always give serious consideration to the

advice of these inspectors and should develop a habit of consulting

with them. If a disagreement develops regarding suitability of tanks

for loading, then it must be referred to the cargo owner and owner/charterer

for resolution. The master may wish to request a surveyor to examine

the tanks on the vessel's behalf to determine tank suitability. On more

than one occasion, ship's tanks have been rejected by loading terminal

representatives because the cargo was not available for loading, or

the cargo was so marginally on-specification in the shore tanks that

it could not be loaded into any vessel without being put off specification.

Part of the function of the tank cleaning matrix is to ensure that excessive

or unnecessary tank washing is not employed. Excessive cleaning wastes

time, energy and accelerates tank structure or coating deterioration.

In the final decision of the level of cleaning to employ, the chief

officer and master must take into account the condition of the ship's

tanks and any special considerations relating to the cargo which they

are made aware of.

For crude oils, the following guidance is provided:

General crude oil trading

Normally, cleaning is not necessary between different types of crude

oils, or between successive voyages. All tanks should be re-stripped

to the slop tank after the vessel has departed and reached warmer waters.

This step alone will recover most of the residual cargo in the tanks.

Crude oil residues may be the most difficult to wash from the cargo

tanks. They combine the high hydrocarbon vapour characteristics of gasoline

cargoes with a potential for leaving sediment and wax. Sediment must

not be allowed to accumulate in the tanks. If heavy sediment was noted

on the previous discharge report, the tanks should be bottom washed

and checked for proper drainage. On trades involving crudes with heavy

sediment, frequent washing of all cargo tanks will be necessary to control

the accumulation in tank bottoms. Alternatively, lighter crudes without

sediment will require little or no tank washing between cargoes. Tanks

which have been crude oil washed require little water washing to prepare

them for clean ballast and limited ventilation before entry. When it

is important to minimise washing water volumes (ie. when slop disposal

ashore is required), then all tanks scheduled for water washing should

be crude oil washed at the discharge port.

Salt water contamination of crude oils

Salt is a contaminate of crude oils. It is important to have crude tanks

as dry as possible before loading. This is particularly true if the

specific gravity of the oil is high, ie. near to that of water. Salt

water is difficult to separate from heavy crude oils and it can cause

significant problems in the refinery. Some crude oils requiring particular

care in this respect are:

Boscan

Tia Juana

Bachaquero virgin gas oil

Preparation of tanks for these and similar crude oils should be conducted

as follows:

a Hot water wash tanks to remove all loose scale, sludge

and sediment.

b Flush the entire cargo system with fresh water.

c Strip tanks dry prior to loading and drain all lines

and pumps.

d Blow lines with air or inert gas.

e Give all tanks a fresh water wash.

f Drain and blow down lines a second time.

If shore lines are to be displaced to the ship, they should all be received

into a single tank. Any slops from the previous voyage should be segregated.

After loading, check each tank for water and record the results. If

excessive water is found, give a letter of protest to the loading terminal.

Crude oils with API's near to that of water (API = 10.0)

a Drain all tanks as thoroughly as possible to remove

the remains of the previous cargo. A bottom flush or bottom wash is

also recommended. Tanks containing heavy deposits of sediment and scale

should be gun-cleaned with water.

b Remove all scale /sediment. If tank entry is involved,

tanks must be gas freed and rendered 'safe for men and fire'. (See section

2.15 for tank entry procedures.)

c After discharge of ballast at the loading port,

and the thorough stripping of tanks and cargo lines, drain all cargo

pumps and pipeline systems.

d Purge pumps and lines with compressed air or inert

gas, giving due consideration to the relevant safety regulations in

force.

e Test all heating coils to make sure they are in

good operational condition.

Cutback asphalt

a Since water is a critical contaminant of this cargo,

it is essential that no water remains in the cargo system. The entire

cargo system to be used for asphalt should be given a line and tank

flush with fuel oil prior to loading. If detailed charterer's instructions

are not provided, then proceed as follows:

b Arrive with tanks free of residues and gas free.

Strip the tanks, lines and pumps as dry as possible. Cargo systems (lines,

pumps, and strainers), must be drained, then blown dry. All cargo valves

must be opened and drained to the cargo tanks. The tanks must be free

of pumpable water.

c At the loading terminal, set the lines for loading

and load 200 to 400 barrels of flushing oil into each cargo tank. Then

transfer the oil from tank to tank , using the ship's cargo pumps, until

all tanks have been flushed. Dispose of oil (ashore or co-mingle with

other fuel oil), according to charterer's or owner's instructions.

Crude condensate

Ras Tanura loadings - special problems

Some crude oil condensate which has a Naphtha base can form chemical

compositions when loaded into cargo tanks that previously contained

crude oil. This occasionally results in the presence of large quantities

of un-pumpable asphalt residues at the discharge port. These residues

are derived from the interaction of the condensate with the ROB from

the previous crude cargo. Asphalt cannot be removed by ordinary cleaning

methods, so the cleaning is very expensive. Therefore, naphtha base

condensate should never be shipped in unclean tanks containing crude

oil ROB.

When condensate is loaded on top of crude oil, or if being topped up

with crude oil, the concentration of the lighter component should not

exceed 10% by volume of the total crude/condensate mixture. This arrangement

must be agreed between owners/shippers/ charterers prior to loading,

because:

a A higher concentration may cause a significant

fallout of heavy, high boiling hydrocarbons, making it impossible to

drain the tanks at the cargo port.

b If a richer mixture is shipped, the high vapour pressure

of the cargo may prevent the use of crude oil washing in the discharge

port, as the P/V valves will lift. Higher tank pressures will prevent

IGS from properly flowing to the tank. Such cargoes should only be carried

in SBT vessels.

Crude oils to be used in the manufacture of lube oils or asphalt

a Gun clean all tanks with hot water - one full cycle.

b Thoroughly flush all pumps and pipelines with water

and pump as dry as possible.

c Remove all sediment, loose scale and sludge from

tank bottoms. If tank entry is required, tank atmosphere requirements

for 'safe for men; safe for hot work' must be met.

d Rinse the entire cargo system with fresh water.

If time allows, give all tanks a fresh water rinse.

e Strip all tanks as dry as possible. Drain all water

from pumps and pipelines prior to loading. Remove cargo piping drain

plugs and pump drain plugs during pre-loading inspection at the loading

berth.

Fuel oil/'black oil' cargoes

Thorough draining is required when changing from crude oil to fuel oil,

or from a fuel oil with a higher number to one of a lower number, such

as from No.6 oil to No.4 oil.

Draining is not required when changing from a fuel oil with a lower

number to one with an equal or higher number.

Accumulation of sediment noted on a discharge report is an indication

of the need for bottom washing of black oil cargo tanks.

Absence of cargo preparation orders

If cargo loading orders have not been received at the time the ballast

voyage begins, the ship should perform only the minimum necessary preparations,

including:

� Flush tank bottoms with water and strip flushings to the slop tank.

� Wash pumps and pipelines to the slop tank.

� Wash necessary tanks for clean ballast (if required).

� Load clean ballast (if required).

� Decant dirty ballast, stripping residues to slop tank in accordance

with MARPOL requirements.

� Flush pumps and pipelines to the sea.

2.9.2 The pumpman and deck crew

The tank washing operation requires the closest cooperation between

the chief officer, pumpman, and the deck crew to operate efficiently

and obtain the required result. The best results will be obtained if

the chief officer prepares a preliminary plan and discusses the plan

with the pumpman and boatswain. The plan should be detailed enough to

indicate the times of starting and finishing the washing operation in

each tank and the sequence of tanks to be washed.

It is not unusual for the pumpman to have completed more tank washing

operations on the vessel in question than the chief officer. In that

case, his assistance is invaluable with respect to knowing how well

the stripping pumps or eductors work, how well the tanks will drain

and which tank washing machines may present problems. Problem tanks

should be scheduled for daylight hours; easy ones can be done at night.

The deck crew may be able to offer suggestions on handling of the portable

tank washing machines, such as where they have been known to become

entangled in tank structure when the ship is rolling. Including the

crew in the planning of the job makes them more interested in seeing

it done well. With proper planning and scheduling, an experienced crew

is capable of conducting all of the mechanical aspects of the tank washing

operation with minimal, general oversight by the chief officer.

When the chief officer has reviewed his plan with the pumpman and crew,

he adds the final details, then discusses it with the master. The final

plan should include both a diagram of the program and a detailed schedule.

On the diagram, mark the time each tank will start, the times of program

changes, or portable machine 'drops' and the time it will finish. Allow

sufficient time between tanks for stripping. Indicate the time when

tanks may be sounded to measure residues (not less than 30 minutes after

finish washing and only with a grounded probe). When the master has

approved the plan, copies are distributed to the watch officers, chief

engineer, engine control room, pumpman, boatswain and one copy is posted

on the crew's (company), bulletin board.

With the program set out in advance, the chief officer is free to concentrate

on verifying the safe conduct of the operation, checking the operation

of fixed or portable machines and ensuring that the next tank is set

up for washing before the previous tank is finished. His primary objective

is the safety of the crew. This is particularly important when washing

with portable machines. The portable machines are heavy, and there are

many opportunities for the crew to create hazardous static electricity

conditions if their actions are not properly monitored and correct procedures

followed. When washing with portable machines, the crew is exposed to

the dangers of broken feet and hands, hot water burns and tank explosions.

The crew must be carefully instructed in safe work practices and provided

with the necessary protective equipment of prevent injury. All personnel

on board should be notified that tank washing operations are to commence

and that all safety precautions as when loading must be observed.

A basic tank diagram chalkboard should be set up on the main deck (one

may be conveniently painted on the side of the superstructure near the

pumproom). The tank washing plan is marked on the chalkboard. The deck

watch marks the chalk board to reflect the current progress of the tank

washing.

If the tank washing program is extensive, or the ballast voyage short,

the tank washing operation should be started immediately after dropping

the outbound pilot and continue nonstop until it is completed. Three

or four men are required in each hose handling operation, so the watch

and crew rotation will need some careful consideration. Handling the

heavy machines and hoses repeatedly for eight to twelve hours at a time

is demanding work.

2.9.3 Tank washing machines

Portable machines

When tankers were smaller and crews were larger, all tankers were cleaned

with portable tank washing machines. Portable machines are connected

to the end of a special tank washing hose. The machines have a bronze

body and the hose couplings are bronze. The hoses are marked at intervals

of five feet or two meters. A natural fibre line must be attached to

the machine for support and ease of handling, even though the hose is

fully capable of supporting the machine unaided. The other end of the

hose is connected to a hydrant on the deck tank washing line or fire

line. The water should be started and the hose flushed through before

the machine is placed in the tank. The machine is then lowered into

the tank through a tank washing opening and supported by a 'saddle'

placed over the opening. The hose is clamped into the saddle and the

machine tether line is made up on the saddle clamp to support the machine.

Tank washing openings are strategically placed in the main deck to permit

good coverage of the tank's inner surface without permitting the machines

to become entangled in the tank's internal structure. The tank cleaning

openings are normally covered by bolted circular covers with gaskets.

The bolts are removed from all the plates to be used, but the plates

should be kept in place until a machine is ready to be inserted into

the opening and the plate replaced promptly after the machine is removed.

The distance the machine is lowered into the tank depends on the size

of the tank and the amount of washing required. For heavy cleaning,

the machine may be placed at three or four successive levels ('drops'),

depending on the complexity of the tank structure. Each drop should

be just above one of the main structural members, so that the upper

surface of these side longitudinals or transverse members are thoroughly

cleaned. If the cargo tank is known to have a heavy accumulation of

sediment, the machines should be lowered to the bottom first and washed

for ten minutes to clear the limber holes of sediment, then raised to

begin the normal wash.

At each level, the machines are operated through a full washing cycle.

The cycle time is determined by the washing pressure. When all machines

are ready, the engine room is asked to start up the tank washing pump

and if necessary the tank washing heater. Sea water is pumped at high

pressure from the engine room, through the heater (if required), into

the deck washing or fire line and into the tank washing hoses. The force

of the water passing through an impeller in the machine causes the offset

nozzles to rotate in a vertical plane and the whole machine to rotate

in a horizontal plane. The jets of water from the nozzles trace a pattern

on the inside of the tank which provides effective coverage of the entire

surface within range of the jets. The maximum range of the jets is normally

nine to ten meters. The washing pattern described by the dual nozzle

rotation resembles a ball of twine.

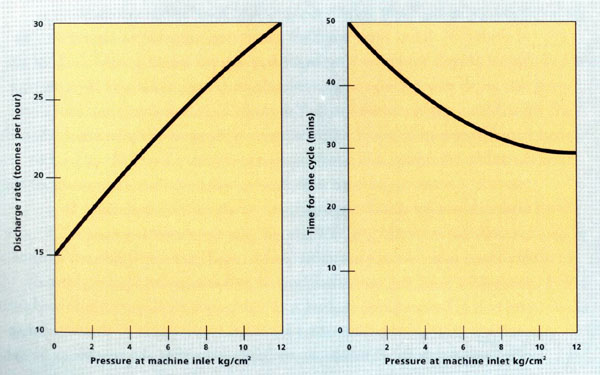

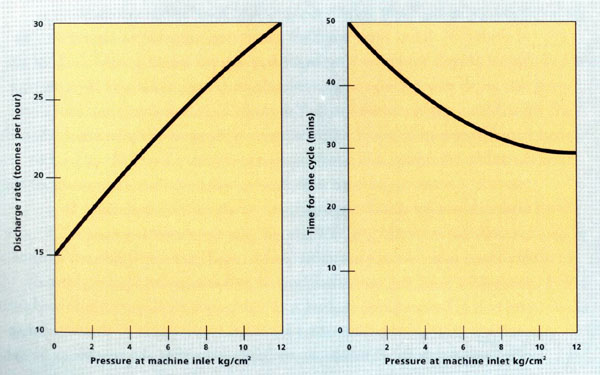

Cycle times for the washing machines are a function of nozzle size and

washing water pressure at the machine. The pressure at the machine will

be lower than the pressure at the pumproom or in the engine room. The

only way to accurately measure the pressure is to have a portable gauge

fitted to the wash water supply line on a spare tank washing outlet

near the machine hose connections. A typical product carrier tank washing

machine with 12 mm nozzles will have a cycle time of 38 minutes at 5

kg/cm sq. (75 psig) and a cycle time of 28 minutes at 12 kg/cm sq. (175

psig).

Higher pressures will produce higher flow rates. The same product carrier

machine will use 20 tons of water per hour at 5 kg/cm sq. and 30 tons

per hour at 12 kg/cm sq.

Example performance curves of a portable tank

washing machine.

For effective tank washing the number of machines used at one time

must not put more water into the tanks than the stripping pump is capable

of removing. By referring to the discharge rate curves for the machines

on his ship, the chief officer can determine the maximum number of machines

his stripping pumps can keep up with.

Complete coverage of the tank surface may not be possible with machines

lowered through the dedicated tank washing openings. It may be necessary

to lower a machine through the tank hatch, or to actually enter the

tank and tie off a machine in a corner of the tank to remove accumulations

in hidden corners. Confined space entry procedures must be used!

It is a good idea to leave the main cargo suction/fill valve open while

the tank is being washed, to drain any residual cargo from the branch

line into the tank. If clean ballast is to be loaded, each tank should

receive a short flush from the sea immediately before or when starting

the washing operation.

Fixed machines

Tank ships larger than 60,000 tonnes are difficult to wash effectively

with portable machines. The number of deck openings required to provide

adequate coverage and the depth of the tanks would require a long and

strenuous effort which today's smaller crews are not capable of supporting.

Tank washing capability for these larger tankers is provided by fixed

tank washing machines, sometimes referred to as 'guns'. Fixed tank washing

machines are mounted on the deck of the ship with control machinery

outside the cargo tank and the rotating parts and spray nozzle inside

the tank. Fixed washing machines are capable of higher washing pressures

and longer effective reach than the portable machines. On crude carriers,

they are carefully placed to provide a washing pattern which covers

the maximum amount of the tank surface by direct impingement of the

washing stream. In accordance with IMO COW system requirements (section

4.2.8), the shadow areas of the tanks

shielded from direct impingement cannot exceed 10% of the tanks horizontal

surfaces and 15% of vertical surfaces. The washing sequence of the cargo

tank is programmed into each machine, depending of its location in the

tank. A tank cleaning operation with fixed machines requires only that

the machines be set to the correct starting position and operated in

the correct order, to provide a complete cleaning of the tank. The fixed

machines can be used to crude oil wash (COW), or to water wash the cargo

tanks, according to the purpose of the washing. Because of the static

electricity hazards of high-capacity tank washing machines, they must

only be operated in properly inerted tanks (see section 2.10.3).

2.9.4 Washing pressures, temperatures and times

The tank washing operation consumes energy and time and erodes the tank

coating or tank structure. It is important that the washing be thorough

enough to properly prepare the tank(s) for the next cargo, but not excessive.

Washing tanks with too high pressure or temperature, or for excessive

time will not improve the result and may cause coating or steel deterioration

which, if repeated often enough, eventually becomes significant damage.

Maximum tank washing pressures are often dictated by the capacity of

the tank washing pump. Higher pressures will reduce machine cycle times

and the overall tank washing time. High pressures will produce a more

thorough cleaning. Washing pressure of 12.6 kg/cm sq (180 psi), is most

desirable for washing crude or fuel oils from un-coated tanks. For washing

clean product tanks, pressures of 9 to 10 kg/cm sq (130 -140 psig) are

suitable. Washing pressure must be maintained below the maximum allowed

for the tank coating material in coated tanks. To properly measure the

tank washing pressure, a gauge must be fitted in the tank washing line

near to the machine connection. Chief officers should refer to the owner's

operating instructions to determine maximum washing pressures. If no

guidance is provided, it should be requested from the owners.

Unless there is a special requirement, tanks should be washed with cold

(ambient) sea water. Cold water washing will normally leave behind only

a waxy skin, which provides a protective film for the steel. Tepid water

(between 30 and 65 �C), is of no practical benefit since it has the

disadvantages of both hot and cold water without providing the benefits

of either.

Maximum tank washing temperatures are often dictated by the capacity

of the tank washing heater and the number of machines in use. Higher

temperatures will increase the effectiveness of difficult washing situations.

Washing temperature must be maintained below the maximum allowed for

the tank coating material in coated tanks. Modern coatings which have

been correctly applied to properly prepared surfaces should have no

washing water temperature limitation and some charterers will not accept

any. If maximum permitted temperature information is not available for

a ship with coated tanks, then use an upper limit of 120 �F (49 �C).

Special caution is required if a coated tank to be washed has carried

a product (such as benzene or toluene), which can soften the coating.

Such tanks should not be cleaned until the coating has 'cured' after

the discharge of the cargo. To properly measure the tank washing temperature,

a thermometer may be fitted in the tank washing line near to the machine

connection, or a bucket filled from the washing line and the temperature

measured by dip thermometer. Chief officers should refer to the owner's

operating instructions to determine maximum washing temperatures. If

no guidance is provided, it should be requested from the owners.

Tank washing times must be calculated based on the washing pressure

at each machine. For portable machines, the tank should be washed until

the machine with the lowest pressure has been able to complete the full

cycle. The portable machines may then be lowered to the next 'drop'

level. Only by permitting the machines to complete their full cycle

is complete washing ensured. Portable machines are usually left at each

drop for a complete cycle, but may be operated at the lowest drop for

two cycles to remove heavy residue or scale accumulation from the tank

bottom.

It is important to check the position indicators on fixed machines to

ensure that they have completed their cycle before stopping the flow

and starting the next machine.

2.9.5 Handling portable tank washing machines

and hoses

Portable tank washing machines and hoses are rugged, precision equipment,

which require proper care and handling to provide safe and effective

performance. Machines should never be dragged along the decks; the best

way to move them from storage to the tank washing area is by use of

a hand truck. They should not be used in tanks with complex structure

while the ship is rolling. The rolling may cause the machines to strike

tank framing; this could damage the machine, damage tank coating and

cause dangerous sparks. The portable machine should be fitted with a

natural fibre line of up to 16 mm diameter. This line is used

to lower and retrieve the machine from the tank, instead of lowering

and pulling it out by the hose. Machines should be flushed with fresh

water after use and dried or given a coating of oil according to the

manufacturers instructions. The pumpman should be given training to

properly maintain the machines and an adequate supply of spare parts

to do so.

Tank washing hoses should be drained and stored in a protected area

between washing operations. Tank washing hoses couplings should be tightened

and disconnected from the washing main using wrenches only, (not hammered

on). Regular replacement of the washers will prevent leaking. To prevent

static electricity hazards, the hose bonding wire continuity must be

verified before each use and the hoses must remain connected to the

washing main at all times while the washing machine is in the tank.

2.9.6 Tank coating protection

Modern epoxy tank coatings are tough and resistant to all of the cargoes

and tank washing procedures to which they would normally be exposed.

However, there are limitations associated with each coating and it is

important that these limitations be readily available to the chief officer

and that he ask for clarification of any questionable circumstances.

For example, certain types of coatings are not approved for carriage

of some jet fuels. Both the coating and the cargo will be damaged by

loading such fuels into the coated tanks. Coatings are also subject

to damage by washing with too high temperature and/or too high pressure

water. To prevent such damage, the pressure and temperature limits should

be readily available to the chief officer and posted at the tank washing

heater/pump in the engine room. The chief officer must remember that

a ship's tank coatings represent a significant portion of the overall

cost of the ship and require his diligent care to protect them from

damage.

2.9.7 Washing with detergents

Detergents should be used only when absolutely necessary. They are normally

applied to difficult tank washing situations, where absolute purity

of the next cargo is required. They are injected into the tank washing

line by a mechanical pump, mix with the washing water and act along

with the water jet to remove the previous cargo clingage and residue.

When using detergents, the chief officer must:

Ensure that the personnel using the chemicals are adequately trained

regarding their hazards and that necessary personal protective equipment

is made available.

Verify that the detergents may be safely used with the tank coatings.

Advise the owner/charterer that the ship will arrive at the loading port

with tank washing slops containing detergent.

Detergents are harmful or poisonous to marine life and should not

be discharged overboard. The presence of detergent in the wash water

increases the potential for static electricity accumulation. To avoid

dangerous accumulations of static electricity, used wash water containing

detergent should not be recirculated from the slop tank for tank washing.

Many loading terminals will not accept slops containing detergents.

For that reason alone, detergents should not be used unless absolutely

necessary.

2.9.8 Washing bunker tanks

Washing bunker tanks is not normally required except to remove contaminated

bunkers, or to clean the tank for repairs. Bunker tanks are not usually

set up with the necessary tank washing openings and the draining of

wash water must be accomplished with the bunker transfer pump. For these

reasons, bunker tank washing may require even more planning than a normal

cargo tank washing. Hoses must be rigged to transfer the wash water

from the bunker system to the cargo stripping system. Since the bunker

tank opening may be in the engine room, special ventilation or ignition

control procedures may be needed to ensure that there is no opportunity

for an explosive atmosphere to be created and ignited.

2.9.9 Inert gas system and vent lines

Part of cleaning a tanker for repairs or shipyard period involves washing

out all tank vent lines and inert gas lines. Even if cargo has not entered

these pipelines as a liquid, cargo vapours are liable to condense in

the lines and form accumulations of hydrocarbons. Cargo tank vent lines

are fitted with washout connections permitting them to be flushed back

to the cargo tank before the cargo tank is washed.

The same flush-out connections are fitted to the IGS line. A tank washing

hose should be connected to each flush-out connection and the branch

lines flushed either into the cargo tank (before tank washing) or back

to the deck non-return valve, from which they must be pumped or drained

to a cargo tank.

2.9.10 Steaming tanks

Steaming cargo tanks produces large accumulations of static electricity.

For that reason, steaming should only be done in inerted tanks.

|