|

5.1 THE DISCHARGE PLAN

The chief officer is responsible for preparing the cargo discharge

plan, according to the owner's guidelines and the instructions of charterers

and Receivers. (See section 2.8)

The principal considerations in the preparation of the discharge plan

are:

Preservation of cargo quality.

Maximum cargo outturn (minimum ROB).

Limitation of hull stress and trim to acceptable levels.

Minimum discharge time.

Safety of crew.

Operation of cargo pumps within acceptable limits.

Maintain freeboard within operating envelope of shore loading arms.

Maintain adequate under-keel clearance in berth.

Achieve vessel performance meeting or exceeding the requirements of

the charter.

Take all precautions to prevent any pollution incident.

Ensure that the vessel remains safely moored throughout the discharge

operation.

Case study

A 33-tank product tanker, carrying 8 grades of products, arrived in Lagos

as the first port of a multi-port discharge programme. Upon docking, the

chief officer was besieged by 7 or 8 receivers, each demanding their products

first. As a result of much shouting and pushing, the only recourse was

to remove all shore personnel from the ship's office and request that

just one representative should attend on everyone's behalf to discuss

the discharge plan, which would finally be decided by the chief officer

according to the many trim and stress considerations of the discharge

programme. It was subsequently discovered that the nearby International

Airport had all but run out of JET A1 inventory!

Case evaluation

The master and chief officer may not always be able to provide a discharge

plan which perfectly satisfies the demands of the receiver(s). In that

case, they must use the plan which protects both the safety of the ship

and the quality of the cargo before any commercial considerations.

5.1.1 Charterer's instructions vs. receiver's

instructions

In most cases, any discharge orders received by the ship will be very

general in nature, indicating only the discharge port and quantities

to be discharged. Occasionally a discharge sequence may be specified.

If there is any discrepancy between the charterer's orders or the cargo

discharge quantities and the discharge sequence requested by the receiving

terminal, then a message requesting clarification should immediately

be sent to the charterer. It is the responsibility of charterer to work

out any differences between their intentions and those of the receiving

terminal. The master should only advise charterer and then await his

instructions. The chief officer's discharge plan must be in accord with

the general instructions received from the charterer.

5.1.2 Trim, list and bulkhead stresses

The cargo tank discharge and ballast tank filling sequence must be scheduled

in a way which minimises the stresses on the hull and keeps the trim

and list within acceptable limits. The first tanks discharged should

be wing tanks forward of amidship. Removal of that weight will reduce

bending stresses and begin to trim the ship by the stern. Discharging

of wing tanks first reduces bulkhead stresses and improves outturn of

heated cargoes.

The chief officer's discharge orders should clearly state that no other

cargo is to be discharged until the tanks designated to be started first

have been well begun. The discharge plan should at an early time achieve

a 6 to 7 meter trim aft to ensure good tank draining. Berth depth restriction

may delay achieving optimum trim until later in the discharge than would

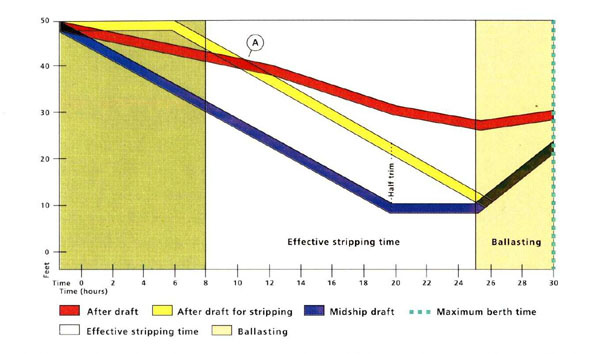

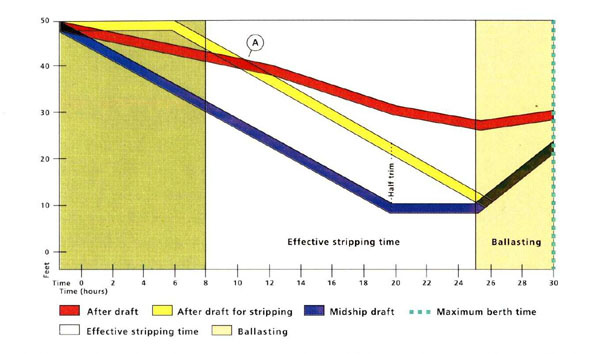

be possible otherwise. Figure 5.1.2 shows a vessel trim programme designed

to achieve good stripping trim of 7 meters in 9 hours without exceeding

15 meters draft aft. The 'midship draft' line is determined by the ship's

overall pumping rate. The 'after draft for stripping' line is parallel

and a one-half of the desired trim (7/2 = 3.5 meters), above the 'midship

draft' line. The 'discharge plan aft draft' line (coloured red) is determined

by calculation of the discharge plan effects on the ship, hour by hour.

1 Above shows draft and trim

during a planned discharge. Draft restriction is 50 feet and time

restriction is 30 hours. 2 The constraint of 50 feet

draft at berth is shown at top of graph. 3 The constraint

of maximum berth time is shown at right of graph. 4

Midship draft is plotted against time. 5 For minimum

draining trim, a line is drawn parallel at half trim to indicate minimum

after draft for effective draining. 6 By effective

discharge sequencing, the after draft intersects the effective draining

after draft at point 'A', which is 8 hours into the discharge. This

gives a time of 16 hours for effective-stripping of cargo before completion

of cargo discharge. 7 The objective of this cargo

sequence is to bring point 'A' to the left and keep draft within the

confines of available depth of water and total time within time constraint.

5.1.3 Discharge plan details

The discharge plan should specify a number of important details and

limitations to be observed in controlling the discharge, including:

Safety procedures to ensure that the discharge plan proceeds without

incident or crew injury.

The critical path for the discharge. The sequence of operations which

should be started as soon as possible and expedited throughout to minimise

total discharge time.

A step-by-step discharge programme, with the setting of all valves

clearly indicated for each step. Valves to be open must be identified

by number and all other valves must be closed. The offloading valve

arrangement should be in the form of a checklist or other format providing

for sign off by the cargo watch officer who starts each operation.

The operating criteria for the pumps including operating speed, tank

levels where main pump is to be stopped and maximum discharge pressures.

Indications of how the main cargo pumps are to be regulated so that

they are used to move the greatest amount of cargo, leaving minimum

work for the stripping pumps.

The sequence for stripping tanks and the stripping accumulation tank(s)

to be used. Clear instruction is necessary regarding the level to which

the stripping accumulation tank must be drained before stripping begins.

Tanks used for stripping accumulation should be fitted with hi-level

alarms.

The ballast programme, with a clear indication of the progress of

cargo discharge to be achieved before ballasting can begin and the correlation

of the ballast sequence to the discharge progress. Procedures for sampling

the cargo during discharge Procedures for changing grades of cargo on

the same cargo system.

When the chief officer is to be called.

Requirements for inspection of pumprooms, sea valves, discharge manifolds

and moorings.

Procedures for emergency cargo pump stop and raising the alarm in

case of fire or cargo spill.

Procedures to avoid limitations due to known leaking pipelines, faulty

valves, or inoperative pumps.

In preparing the discharge plan, the chief officer refers to the records

of the vessel's previous performance at the port and with the-cargoes

to be discharged, as well as the pump's 'flow rate/head at the ship's

manifold' curves (if available). With that information, he estimates

the pumping times required to discharge the current cargo. The chief

officer considers any mechanical limitations while preparing the planned

discharge programme.

The final cargo discharge plan should include a time bar graph of the

cargo discharge, COW programme (if applicable) and the ballast programme.

This diagram should be drawn on a single sheet so that he interrelationship

between the various activities can be clearly seen and appreciated by

all involved in the discharge operation.

A simple discharge sequence bar chart.

5.1.4 Heated cargo programme

The programme for discharging heated cargo should include consideration

of:

Discharging wing tanks first, because of the more rapid heat loss

of the wing tanks.

Early reduction of steam to the heating coils of cargo with a high

vapour pressure, to reduce the chance is suction loss due to gassing

of the pumps.

Discharge of the more viscous grade of heated cargo first, so that

the ship's lines can be cleaned by the less viscous cargo following.

|