|

5.28 STRIPPING CARGO

The strategy employed in completing the discharge of cargo will determine,

to a large degree, the impression the charterer and the facility will

have of the ship's performance. A carefully planned and competently

completed tank stripping (draining), operation will ensure a minimum

discharge time and maximum cargo outturn. A full knowledge of the characteristics

of the cargo and the capabilities of the ship's pumping systems are

essential to achieve maximum outturn with minimum time in berth.

5.28.1 Types of stripping systems

A tanker may have a stripping system made up of independent suction

piping, or it may have alternative stripping suction outlets from the

main cargo lines.

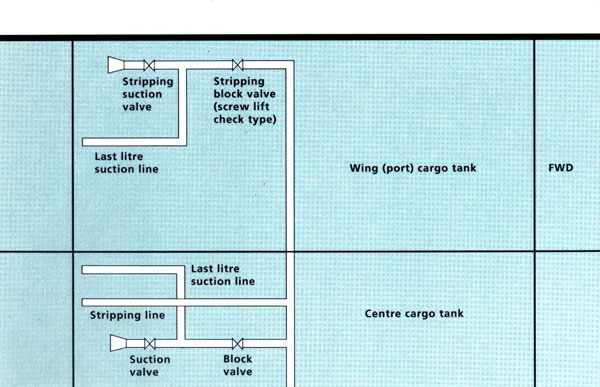

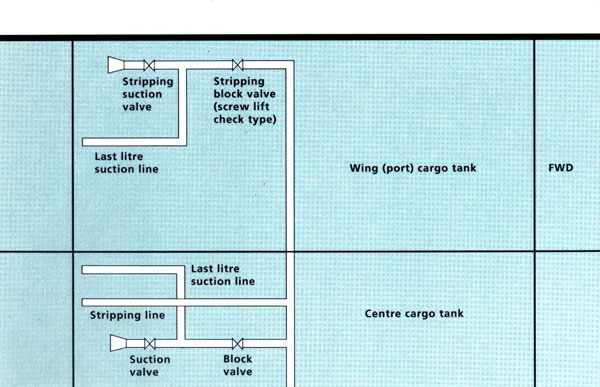

Simplified diagram of suction piping with an independent

stripping system.

The first alternative is the most versatile and permits the earliest stripping

of tanks after they have been emptied as far as possible by the main cargo

pumps. To use a stripping system off the main cargo lines, the main pumps

must be either finished their work or stopped. This will tend to delay

the discharge.

Stripping suction valves in tanks should be 'globe/check' valves, a special

type of valve which acts as a non-return valve when opened only a few

turns, but permits full flow when fully opened. These valves are opened

fully when stripping begins, then closed to the check position as the

tank becomes nearly empty.

Simplified diagram of suction piping with main

and stripping lines combined. One pipeline

system has both main (large diameter) and stripping (small diameter)

suctions.

Some stripping systems are fitted with 'last litre' (or 'last gallon')

suctions, small diameter suction lines connected between the stripping

suction valves and a stripping suction block valve. When the tank appears

to be empty, the stripping suction valve is closed, leaving the block

valve open. The pump then draws through the 'last litre' line suction

located in the very corner of the tank a few millimetres above the tank

bottom.

Either type of stripping system will normally have two stripping pumps

in the pumproom, arranged so that they can be used simultaneously and

separately on different groups of tanks.

The stripping discharge piping will include lines to the midship manifold,

to the slop tank(s) and possibly to an aft cargo tank which can be used

for a stripping accumulation tank. There may also be a stripping overboard

discharge line. The overboard valve(s) must be verified to be fully

closed and sealed before the stripping pumps are started.

'Last-litre' stripping line used for maximum recovery

on product tankers. When the suction valve

is closed, with the block valve open, the stripping pump suction acts

on the small-diameter line, achieving maximum cargo recovery.

5.28.2 Stripping pumps

Most stripping pumps are based on an operating principle called 'positive

displacement'. The oil which enters the pump is mechanically moved from

the suction side to the discharge side. This action creates a vacuum

at the suction side of the pump, enabling the pump to 'lift' cargo from

the tank into its pumping chambers.

The typical positive displacement pump is a reciprocating pump, normally

of duplex (two pumping chambers), double-acting design. The internal

mechanism is designed so that the cargo piston pumps on both the upstroke

and the downstroke. The key components to the proper function of reciprocating

pumps is the condition of the internal cargo valves. These should be

examined regularly to ensure that their springs and seating arrangements

are in good order.

Duplex reciprocating pump.

Reciprocating pumps are steam powered. To reduce the hazard from hot

steam lines in the pumproom, the lines must be completely and tightly

insulated to prevent vapourisation or ignition of any cargo leaks which

could spray or flow onto them.

A second type of stripping pump is a rotary or gear pump. These usually

consist of two meshing gears which move the cargo between the pump casing

and the gear teeth as the gears are rotated. These pumps are usually

powered by an electric motor. They are very efficient and particularly

suited for pumping high viscosity oils, such as lubricating oils or

molasses.

A third method of stripping tanks does not use a pump at all, but a

device called an eductor. The eductor obtains its vacuum or 'lift' by

use of a drive fluid, normally the stream of cargo from the main cargo

pump discharge. The principal advantage of the eductor is that it cannot

lose suction or be damaged by being run dry. The disadvantage is that

once the main cargo pump is stopped, there is no drive fluid available

and no further stripping is possible.

5.28.3 High-pour cargo

Effective stripping of high-pour-point cargo begins with achieving the

correct cargo discharging temperature. The cargo must be heated to and

maintained at the recommended discharge temperature until the cargo

surface reaches the level of the heating coils. (Steam to the heating

coils must be shut off just before they are exposed by the receding

cargo.)

Tanks must be discharged systematically, so that a stripping pump is

immediately available when the tank is at minimum main cargo pump level.

It is usually desirable to line up and start the stripping pump before

the main cargo pump is switched from the tank, so that the stripping

pump is already working when the tank reaches the stripping level. Each

tank should be stripped as dry as possible, then re-stripped two or

three times at thirty minute intervals.

If the shore requests a discharge stop before stripping is complete,

protest the delay, indicating that it will increase the vessel's ROB.

If the stop is essential, the best course is to begin stripping to an

accumulation tank. If sufficient strippings can be accumulated to cover

the heating coils in the accumulation tank, cargo heating can be resumed.

After all tanks have been stripped, recirculate cargo via the deck discharge

line and loading drop to prevent line blockage until discharge ashore

can be resumed.

It is particularly important to arrange for effective COWing of waxy

crude oils so that the tank bottom wash occurs as soon as possible.

If this is not done, the formation of wax in the cooling oil will block

the limber holes, preventing the flow of cargo to the tank suction inlet.

The following crude oils are known to congeal rapidly as their temperature

approaches the pour point, so rapid stripping is essential:

| Cargo |

Origin |

Discharge temperature �C |

Pour point �C |

| Bahia |

Brazil |

60 |

24 |

| Cabinda |

Angola |

33 - 44 |

27 |

| Gamba |

Gabon |

32 |

16 |

| Midas Crude |

Indonesia |

52 - 57 |

35 |

| Rio Zulia |

Columbia |

44 - 49 |

27 |

| San Juaquin |

Venezuela |

41 |

24 |

| Sarir |

Libya |

38 |

21 |

| Zeta North |

Venezuela |

38 |

21 |

| Daquin Crude |

China |

52 |

32 |

It is essential that tanks with these cargoes be immediately drained

after they have been drawn down to the bottom longitudinals.

If the best efforts of the stripping programme do not prevent heavy

clingage of un-pumpable ROB, then the only recourse is to back-load

500 to 1000 tonnes of light crude oil or light gas oil into the slop

tank and closed cycle COW with this wash oil until the ROB/ clingage

has been reduced to an acceptable level. After washing, the slop tank

is measured to determine the gain from COWing and then discharged ashore.

After completion of high-pour cargo discharge, immediately circulate

hot water (74 �C), through all deck lines, pumps and risers, stripping

all water and residue to the slop tank.

5.28.4 Stripping high vapour pressure cargoes

Stripping high vapour pressure cargo requires pumps that are in good

mechanical condition and are carefully operated. Pumps should be operated

at slow to moderate speed, else the rapid piston action of the reciprocating

pumps will tend to 'flash' the cargo in the cylinder, forming vapour

or gas. The vapour or gas reduces the effectiveness of the pump and

may cause it to lose suction entirely be becoming vapour bound. It is

particularly important to keep enough cargo in one tank for priming

the pumps when stripping high vapour pressure cargo.

Keep stripping pumps separated; making their suction lines common increases

the tendency to become vapour bound. The discharge valve of the pump

may be closed slightly to provide additional back pressure to improve

pump performance.

Increasing the inert gas pressure in the tanks being stripped will increase

the effective positive suction head in the tank and reduce the tendency

to cargo vapourisation, however if COWing is being performed it will

add additional pressure to the tank, which could cause the pressure

relief valve to lift.

5.28.5 Accumulation tank

Cargo tanks can be stripped most efficiently when the ship is discharging

a single cargo. As the tanks are emptied by the main cargo pumps, they

can be stripped to an accumulation tank, which in turn can be discharged

with the higher capacity (centrifugal) main cargo pump. When stripping

to an accumulation tank, it is important that the tank be discharged

to between 1/2 and 2/3 of total depth before stripping begins. This

provides space to receive strippings.

The ullage of the accumulation tank must be carefully monitored to avoid

an overflow. One method of avoiding this is to slightly open the accumulation

tank main suction valve to an active cargo pump. This will keep the

tank at about the same level while stripping and will help to keep the

main cargo pump primed.

5.28.6 Shore back-pressure

Shore back-pressure is occasionally so high that it is very difficult

or impossible for the stripping pumps to move the final cargo residues

ashore. Port Jefferson, New York is a good example of this. The 60 psi.

of shore back-pressure there can only be overcome by stripping pumps

in top condition.

To overcome high shore back-pressure, the best recourse is to use a

stripping accumulation tank on board to receive all of the tank strippings

and all of the pipeline drainings except for one discharge line. The

accumulation tank should be at least 14 filled when finished. If necessary,

stop the discharge with the main cargo pump to retain that amount of

cargo. (Remember that outturn is more important than turnaround time!)

When all strippings have been accumulated, start the main cargo pump

on the last tank, discharging via a single cargo line to shore. Monitor

the MCP performance carefully, reducing its speed and adjusting the

pump discharge valve to maintain suction and discharge pressure as long

as possible. When the MCP loses suction, the stripping pump can attempt

to strip the remaining cargo in the accumulation tank ashore, followed

by the remaining cargo pipeline(s) stripped ashore via the small-bore

MARPOL discharge line, (see section 5.31).

5.28.7 Other stripping considerations

Stripping operations will be more successful if the ship is properly

trimmed and listed. The largest trim aft, acceptable within the vessel's

stress limitations, will provide the best draining of tanks. On a 240

meter vessel, four meters of trim aft represents only one degree

of slope to aid the flow of cargo to the suctions. One degree is ,not

much! More trim provides better draining! The ship should be listed

to port or starboard, or trimmed with no list depending on the location

of the tank suctions.

A Tanker with deadrise - ranks

are stripped with no list on the ship. B Tanker without

deadrise - port list required for effective stripping. Stripping suction

location depends on hottom design and desired list (port and starboard)

for best cargo recovery.

In some ships the tank suctions are located in the aft, port cornei

of each cargo tank. It is important that these ships be listed to port

when stripping to achieve the best drainage. Other ships have the stripping

suctions in the inboard corners of the wing tanks and at th centre of

the centre cargo tanks. These ships must have zero list for best stripping.

The cargo watch officer must know the suction locations in the tanks

and the chief officer should include stripping trim instructions in

the discharging orders. If a list is required for stripping, the aft

wing tanks should be retained to provide it. At the same time, the tanks

can perform additional service as pump priming tanks. Record the amount

of stern trim in the logbook every two hours while stripping.

Automatic ullage tape floats will tend to stick to the bottom of the

tank after discharging heavy or viscous cargo. Have the pumpman roll

up and secure the tapes immediately after stripping is completed.

The pulsating discharge pressure of reciprocating pump can occasionally

set up a harmonic oscillation in cargo transfer arms. The deck watch

should be instructed to watch for this and to advise the cargo watch

officer if it begins. The oscillation can normally be stopped by reducing

the speed of the stripping pump.

If stripping with an eductor system, use the smallest tank possible

to provide drive fluid for the eductor during the final stripping. This

final tank will have to be drained with the main cargo pump, making

complete draining unlikely. A No.l wing tank makes a good choice. With

the ship trimmed aft, it will have a good elevation above the pump and

the small bottom section of the wedge-shaped wing tank will have the

least volume/depth ratio of all tanks on the ship, leaving the least

cargo on board when the MCP loses suction.

If a charterer or terminal representative is on board, he should be

encouraged (or challenged), to witness and confirm that the stripping

operation was thorough and successful. This will, at the least, put

to the test his commitment and the authority of his position. It may

avoid the difficulties of proving effective stripping efforts and results

to the independent inspector at the final survey. Independent inspectors

will rarely undertake any form of initial survey (inspection before

completion of discharge), on behalf of their clients.

5.28.8 Stripping deepwell pumps

A well maintained and properly operated deepwell pump will drain a cargo

tank almost as dry as a reciprocating stripping pump. At the end of

the discharge there may remain a small amount of cargo in the tank and

the pump well will be full, or partially full, of cargo. Some vessels,

particularly chemical tankers, are fitted with small, air operated reciprocating

pumps in the tank adjacent to the deepwell. Using reach-rods from the

deck, the pumpman is able to first take suction from the tank bottom

with this pump, completing the stripping of the tank. Then he can open

a suction valve to the deep well and pump its contents (and in some

cases the contents of the discharge line), to the discharge manifold

via a small diameter line.

The small stripping discharge line is connected to the discharge manifold,

outboard of the manifold valve.

|