|

4.10 IGS OPERATIONS

During the loaded passage, the inert gas present in the cargo tanks

may be expelled and outside atmosphere pulled in to replace it due to:

Ľ Changes in tank pressure due to air temperature variations or changing

temperature differences between the sea and air, or

Ľ Rolling and pitching in rough seas.

The cargo tank oxygen content and tank atmosphere pressure should be

frequently checked during the voyage. If an increase in oxygen content

is noted, the inert gas generator system must be placed in operation

long enough to reduce the cargo tank oxygen level to an acceptable level.

An IGS positive pressure of at least 100 mm water gauge must be maintained

during the loaded passage.

Normally the tanker will have a small 'make-up' IGS blower for the purpose

of topping up tanks during the loaded passage. The IGS system should

be secured as soon as the oxygen level is below 5% in all tanks. Excessive

running to the IGS system on loaded passage will increase vapour losses

for the voyage.

4.10.1 IGS maintenance

At the end of the loaded passage, proper operation of the IGS system

will be essential to a successful discharge operation. All tankers are

required by charter party to discharge cargo as rapidly as possible.

The vessel can only meet this requirement if the IG system is capable

of providing IG as rapidly as the cargo pumps can discharge the cargo.

During the loaded passage, the chief engineer should complete all necessary

IGS maintenance checks and immediately investigate any suspicious or

sub-standard performance.

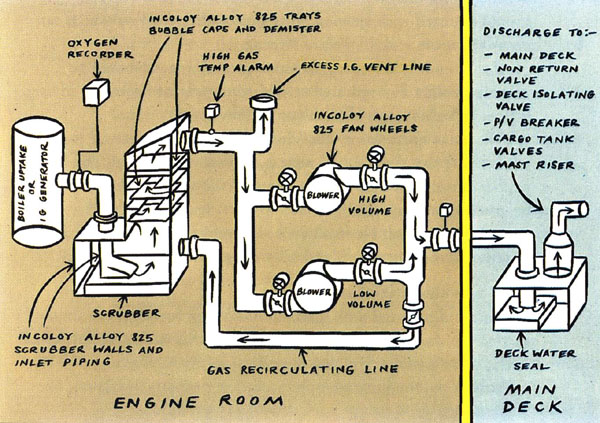

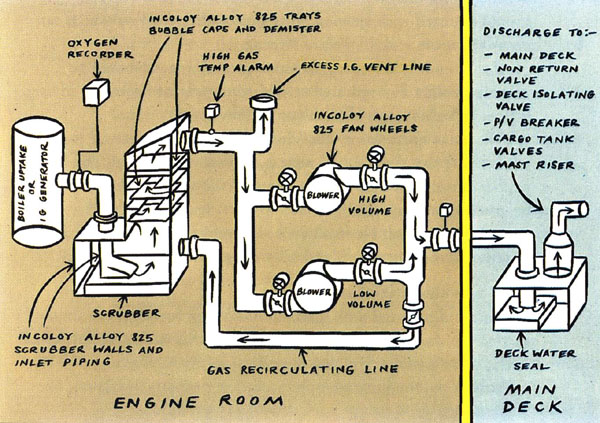

A typical arrangement for an inert gas system.

Significant failures of the IGS system should be reported immediately

to owners and charterers.

IGS system components to be checked include:

Ľ Scrubber unit.

Ľ Blowers.

Ľ Deck water seal.

Ľ Non-return valve.

Ľ Scrubber effluent line.

Ľ Oxygen sensor and meter.

Ľ Alarm systems.

|