|

5.38 CARGO OUTTURN

Next to delivering the cargo to the desired quality specification,

the most important requirement for a tanker is delivering the manifested

amount of cargo to the shore tanks.

The contributing factors to a good cargo outturn is discussed in several

earlier sections of this book. They include:

Ģ A good tank sediment control programme.

Ģ Proper cargo heating procedures.

Ģ Tight cargo lines and efficient pumps.

Ģ 100% COWing of crude oil tanks, where desirable and approved.

Ģ Correct trim and list while stripping tanks.

Ģ Accurate cargo measurement procedures and records.

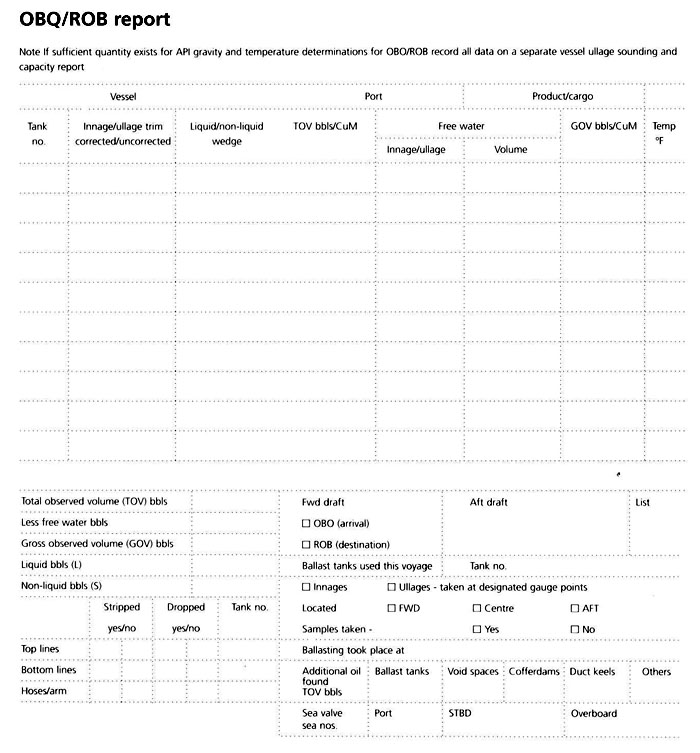

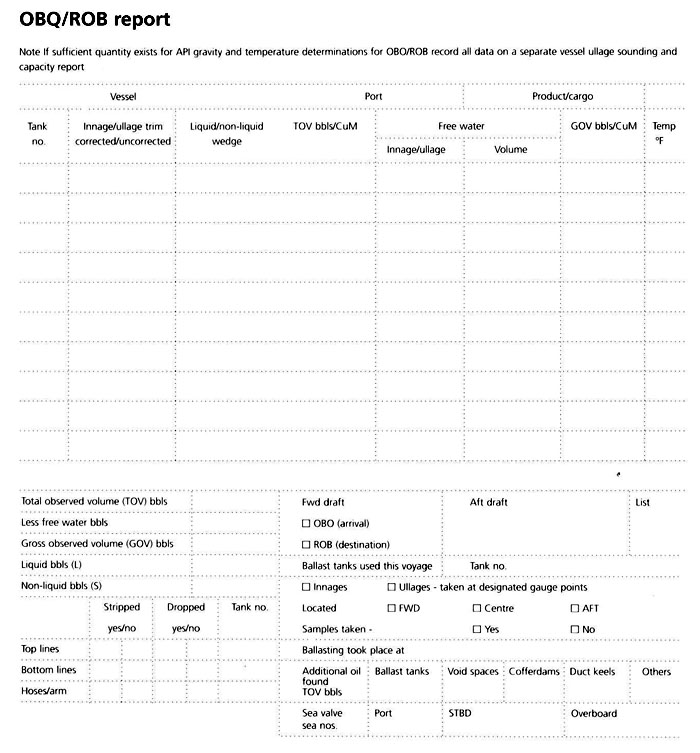

5.38.1 ROB measurement

Many ROB measurements are done in a way which may not be reflective

of the true conditions in the bottom of the tank. Accuracy of ROB measurements

can be improved by:

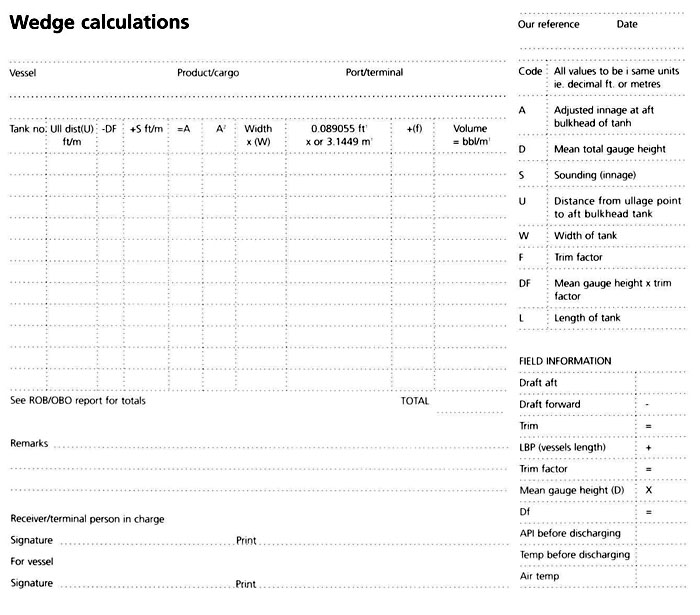

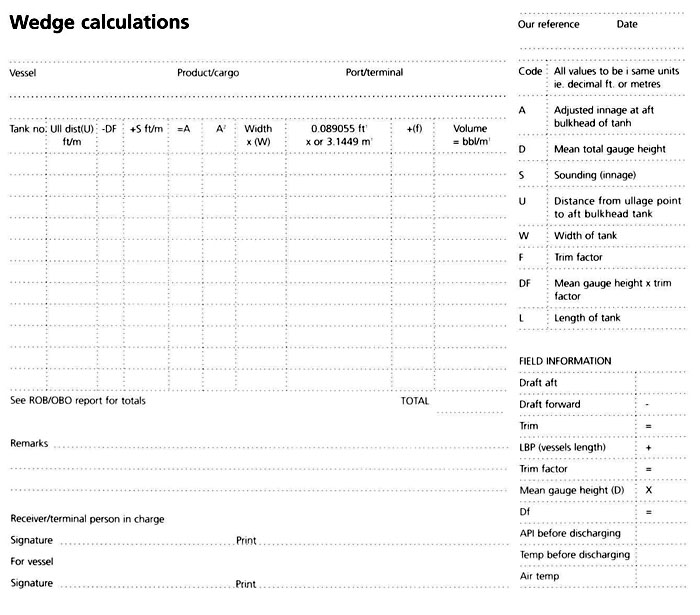

Ģ Use of innages rather than ullages for ROB depth measurement. If ullages

are used, a correction for vessel trim (cosine of the trim angle multiplied

by the measured ullage), should be applied (though it is not in the

vessel's advantage to correct the ullage). Measurement of sediment,

semi-solid, or liquid ROB at five measurement points in each tank.

Ģ Application of the wedge formula to only the liquid phase of the ROB,

taking the sediment thickness in the dry portions of the tank as also

lying under the liquid.

Sampling the ROB (attempt to obtain a clear sample of any liquid phase).

The usual procedures for making ROB measurement neglect one or more

of these recommendations, making the area of ROB volumes one of the

most dispute filled parts of tanker operations.

5.38.2 Vessel experience factor

At each discharge port, the vessel should have available a summary record

of previous cargo loading and discharge volume figures for examination

by the independent petroleum inspector. These records are used to prepare

a vessel experience review and vessel experience factor (or ratio).

Separate experience factors are calculated for the loading port and

discharge ports:

Ship loading port volume as a ratio of shore loading volume. Ship arriving

volume as a ratio of shore receipt volume.

See section 3.29.7 for the details

of experience factor calculation.

Over a period of time, for a number of similar cargoes (usually ten),

the ratio should be relatively constant. For example, all of the ratios

between the ship's arrival figure and shore tank received volume for

Arabian Gulf crude oils should be in close agreement. A discrepancy

of more than 0.3% is cause for further investigation.

If the ratio of vessel's arrival volume to the shore received volume

is inconsistent with its previous discharge port VEF, then several possibilities

exist. If the other ratios for the voyage are consistent with the ship's

corresponding VEFs, then the shore tank receiving figures are suspect.

If the ship loading to discharging ratio is also inconsistent with previous

experience, then the ship arrival volume calculations are suspect. Vessel

experience factors should provide reassurance that cargo measurements

are consistent with previous experience, or indicate where an error

in measurement or calculation may have been made.

5.38.3 Shore tank figures and shortages

While the cargo measurements made from the shore tanks when loading

or receiving cargo are used for custody transfer of the cargo, there

are many opportunities for inaccuracy in such measurements.

Tank bottom errors

The shape of a shore tank's bottom changes over time as the tank's foundation

ring and bottom plating subside, tilt, or shift to conform to the supporting

earth. Shore tank bottoms should be regularly recalibrated and new calibration

tables issued. If a ship discharges into an empty shore tank the received

volume may be more or less than the actual volume due to outdated calibration

tables. Calibration tables should be stamped, or otherwise endorsed

on each page with the seal of an independent petroleum inspection service

and the date of the tank calibration. Calibration tables which are more

than ten years old should be considered as a possible source of measurement

error.

Measurement error

Can be due to use of incorrect tapes, taking too few temperature measurements,

failure to check the measured ullage against the automated innage tape

and the registered tank depth, or incorrect free water measurement.

Shore ullage tapes should be checked with the same diligence as with

ship measurement tapes. Electronic ullaging/temperature units must have

a recent calibration certificate, or be verified against certified thermometers.

Temperature measurements must be made at a sufficient number of points

around the tank to obtain a representative sampling of each area. If

an unheated cargo is discharged into a shore tank in a warm climate,

thermal stratification in the tank can be expected and several temperature

measurements at appropriate levels at each measurement point will be

necessary.

Empty pipelines

If pipelines are not proven to be full ('packed'), at the start of the

discharge, but are indicated as full in the receiving calculation, then

the ship will not be credited with the volume of cargo needed to fill

any empty portion of the shore pipelines. The shore terminal must cooperate

with the independent petroleum inspector to verify that shore lines

are filled before the ship begins discharging.

Floating roofs

Floating roofs that are uncovered ('open floaters'), are subject to

measurement variations due to weather, including rain, snow, ice accumulations

or run off and wind. Variations are larger if the tank is close to full.

Floating roofs act as a known weight on the tank content surface. The

roof displaces its own weight in product and forces the product higher

up in the tank stilling well or gauge point neck. The amount of surface

height difference is a function of the product density and the weight

of the roof. The difference is calculated for the product normally stowed

in the tank. If none of the weather conditions change during the discharge,

there will be little error in measurement as long as the roof is afloat.

If weight is added to or subtracted from the roof during discharge,

it will produce a substantial error in the calculated amount the tank

receives. For example, discharging a warm cargo into a tank whose roof

is snow or ice covered may cause some of the snow or ice to melt. If

the roof water drains have been left open, the water will run off, the

roof will float higher, the product level will fall in the stilling

well and there will be an apparent loss on the delivery outturn! The

more tanks affected, the greater will be the loss. The reverse effect

will occur if a heavy rainfall is permitted to accumulate on a floating

roof which was dry at the start of the discharge.

Shore error

On occasion, shore terminal operating personnel make mistakes. Valves

are accidentally left open and the ship's discharge stream is directed

to unintended areas. If this is discovered by the shore operators before

the end of the discharge then they may correct the problem without advising

of the error or making the necessary adjustment to the shore receipt

figures.

Shore theft

At the end of any year, a shore terminal is expected to have generated

positive variation gains from the cargoes handled. These gains are normally

taken into the inventory of the terminal owners/operators as part of

their operating 'profit'. Like a casino, an intelligently run terminal

knows how to use measurement discretion and tank and pipeline features

to realise gains without breaking the rules (see section 3.29).

On occasion, however, a terminal may be less than honest in their handling

of the cargo, to the detriment of the shipper and the ship owner. These

rare events are, however, a principal reason for cargo interests employing

cargo auditors to support the work of independent petroleum inspectors

at a tanker delivery.

|