|

3.20 TENDING MOORING LINES, HOSES AND GANGWAY

During the loading operation, the mooring lines, cargo loading hoses/arms

and gangway must be carefully checked and regularly tended to prevent

the ship from moving (ranging), along the berth.

3.20.1 Mooring lines

In most cases, the loading operation causes the mooring lines to become

slack as the weather deck of the tanker moves down toward the level

of the dock. This reduces the pressure of the ship's hull against the

dock face, and its resistance to being moved along the dock by tide,

current, or passing ship traffic.

If the vessel is loading at high rates or there is a large tidal range

and the mooring leads are short, some member of the cargo watch should

be assigned to continuously adjust the moorings to maintain

the ship securely alongside the dock.

The lines must be adjusted in a way that does not move the ship in the

berth or put an excessive strain on any single mooring line or dock

bollard.

After adjustment, winches should always be left with only the brake

engaged. Power should never be left on a winch to 'automatically' tension

it, nor should constant tension winches be left in the automatic position

while moored and loading.

The tendency of the ship to be moved by passing vessels increases as

the under-keel clearance of the moored ship decreases. The time when

loading is nearly finished and the crew is distracted with final cargo

operations and departure preparations is the time when the vessel is

most likely to be carried off the berth by any large ships passing at

high speed. If the loading berth is parallel to an adjacent ship channel,

the deck watch must watch for passing traffic and stand by the mooring

winches when large vessels are seen approaching.

Manning of the cargo watch should be arranged so that there are sufficient

personnel available at all times to properly attend both the mooring

lines and the cargo operation. If necessary, stop loading so that all

watch personnel can tend mooring lines.

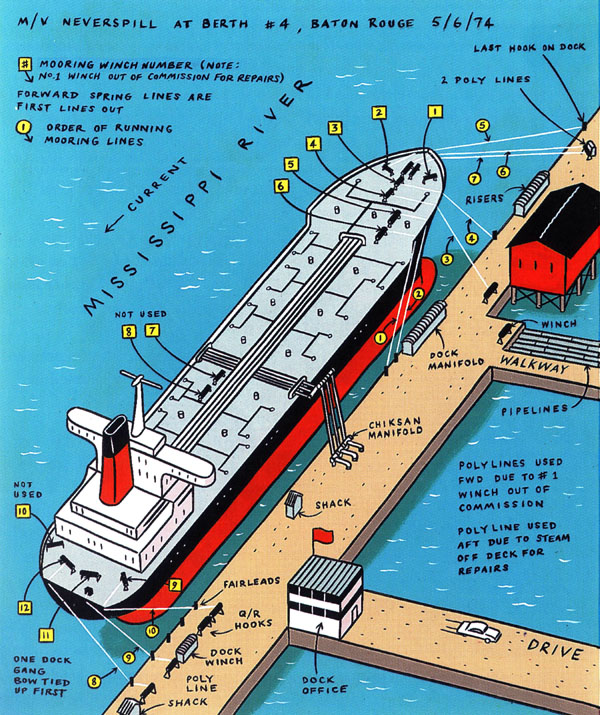

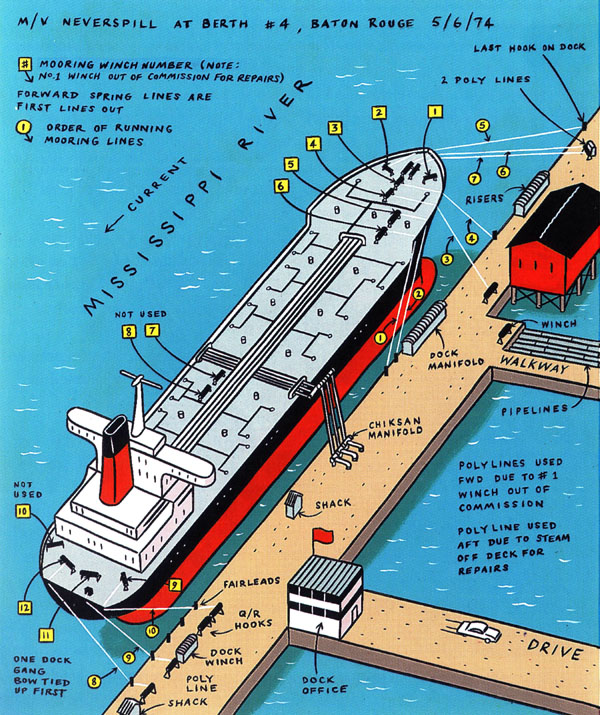

Mooring plan sketch of an unusual mooring arrangement.

(Note the lack of back springs in this mooring.)

Moorings should be made tight immediately before topping off tanks,

so that the entire deck watch will be available for the topping off

operation.

If the ship cannot be safely moored alongside due to stress of weather

and/or tide, or insufficiency of shore mooring points, then the master

must stop the loading operation and if necessary vacate the berth until

conditions have changed sufficiently that the ship can again be properly

and safely moored.

Where a berth is exposed to weather and sea from one direction, the

master must carefully observe the weather forecast and be prepared to

leave the berth if severe weather is forecast from the offshore direction.

A ship which remains in a berth in the face of a developing storm may

find, at the last moment, that tugs are unable to work alongside and

the vessel is trapped against the berth and at the mercy of wind and

waves. Both tankers and berths have been severely damaged in this way.

When loading by loading arms, the alignment of the arms must be frequently

checked to ensure the ship is not creeping forward or aft due to uneven

tending of the mooring lines. Both ship and shore must be aware of the

loading arm operating envelope and take timely action to see that the

maximum limits are not exceeded.

At single point moorings, a continuous watch must be maintained over

the buoy and mooring hawser by a crew member stationed in the bow.

3.20.2 Hoses and loading arms

Although their construction is robust, loading hoses must be seen as

a fragile conduit between the tanker and the loading terminal.

When the ship is being loaded with hoses and begins loading with its

main deck well above the dock, the cargo hoses must be frequently checked

to see that any slack does not fall between the hull and the dock face.

When the dock is well above the ship's manifold (as at Baton Rouge),

the hoses must be checked to ensure that they have not become too become

tight.

Hoses must be properly supported to prevent excessive bending, kinking,

or chaffing. As their position changes, verify that they do not come

in contact with any pointed or sharp-edged parts of the ship or dock

structure.

Wire slings should never be used directly against the rubber carcass

of the hose.

Loading arms once connected and properly supported should need no further

adjustment. However from time to time the tightness of the support jacks

should be checked to ensure that the weight of the arm is being fully

supported by the jack, with little or no weight on the manifold connection.

The tanker freeboard and position at the dock

must be controlled to maintain the loading/discharge arm within its

normal operating envelope.

The loading orders should include any restrictions on draft or freeboard

necessary to avoid exceeding the operating envelope of the loading arms.

It is the responsibility of the cargo watch officer to see that the

ship's amidship draft is maintained within the indicated limits.

3.20.3 Gangway watch

The gangway should be located as far as possible from the loading manifold

so as to separate the personnel traffic from the most probable source

of hydrocarbon vapours.

The location of the gangway should include considerations of escape

by vessel crew in the event of an emergency and access by shore emergency

personnel. The location should be within the protective range of ship

and shore fire monitors.

The gangway watch is a vital part of the vessel's security system. The

master should consult with the agent to determine the level of security

and attendance that is necessary. It is also important that government

officials, authorised representatives, new crew members and marine authorities

boarding the ship are properly received, logged aboard, provided with

safety equipment (as company policy indicates) and escorted to the office

of the person they ask to see. No one should be allowed aboard without

an identification check and no visitors should be allowed unless invited

or approved by the master. A contract security person or properly instructed

crew member should be within sight of the gangway at all times. A copy

of the ship's fire fighting and safety plan must be placed in a red,

watertight container marked 'FIRE FIGHTING PLAN' and kept at

the head of the gangway while in port.

In most petroleum terminals, personnel must pass terminal security before

reaching the loading berth, so unwelcome visitors are unlikely to be

able to reach the dock. The ship may request that all persons reaching

the dock sign in at the deck office and be announced to the cargo officer

by radio before being authorised to proceed up the gangway. If a shore

watchman is stationed at the gangway, he must be carefully instructed

in his duties and provided with a means of contacting the cargo watch.

Any member of the crew who returns from ashore in an intoxicated condition

must either be escorted to his quarters and instructed not to leave

them until he has 'slept it off, or refused access to the ship and turned

over to an agency representative for care and custody until he recovers

(see section 2.5.2).

If the shore gangway is used, the ship's crew is responsible only for

watching the end secured to the ship. If the ship's gangway is used,

the crew is responsible for watching all parts of it to prevent a dangerous

condition from developing or damage occurring. At the loading berth

it is easy for the lower end to become jammed and for the gangway to

be severely damaged as the ship's freeboard decreases.

A proper safety netting must be rigged under the gangway between the

ship and the dock and the gangway must be adequately lighted at night.

Any grease or oil left on the hand rails/ropes by careless dock workers

must be quickly wiped off. If freezing weather the gangway treads should

be salted or sanded as necessary.

A sign indicating:

No visitors

No open lights

No smoking

should be posted at the bottom and top of the gangway, facing arriving

personnel. The upper sign usually has the sailing board on the reverse

side to indicate to crew going ashore the time and date of the vessel's

anticipated departure and the time they are required to be on board.

Aluminum gangways should be protected (by wood or plastic strips), from

rubbing against steel railings, decks, or coamings. The aluminum smear

left by the gangway can make an incendive spark if struck a sharp blow.

3.20.4 Signals

Required flag and light signals must be displayed by tankers at all

times while in port, whether at anchor or alongside the berth (see section

3.8.1.29).

3.20.5 Emergency towing wires

Towing wires for emergency use should be make up with five turns on

the offshore bow and quarter bitts, with the offshore eye suspended

one meter above the water surface and adequate slack held back by a

light fibre line. Towing wire should be 28 mm or greater diameter.

3.20.6 Anchors

While in berth, anchors must be secured to prevent them from running

out in case of accident.

|